Wet Electrospinning and its Applications: A Review

Electrospinning húmedo y sus aplicaciones: una revisión

Received: October 29, 2021

Accepted: June 07, 2022

Available: June 28, 2022

M. L. Mejía-Suaza; Y. Hurtado-Henao; M. E. Moncada-Acevedo, “Wet Electrospinning and its Applications: A Review,” TecnoLógicas, vol. 25, nro. 54, e2223, 2022. https://doi.org/10.22430/22565337.2223

Abstract

In wet electrospinning, a natural or synthetic polymer solution is deposited on a non-solvent liquid coagulant used as collector. This technique can create 3D nanofiber scaffolds with better properties (e.g., porosity and high surface area) than those of traditional 2D scaffolds produced by standard electrospinning. Thanks to these characteristics, wet electrospinning can be employed in a wide range of tissue engineering and industrial applications. This review aims to broaden the panorama of this technique, its possible fields of action, and its range of common materials. Moreover, we also discuss its future trends. In this study, we review papers on this method published between 2017 and 2021 to establish the state of the art of wet electrospinning and its most important applications in cardiac, cartilage, hepatic, wound dressing, skin, neural, bone, and skeletal muscle tissue engineering. Additionally, we examine its industrial applications in water purification, air filters, energy, biomedical sensors, and textiles. The main results of this review indicate that 3D scaffolds for tissue engineering applications are biocompatible; mimic the extracellular matrix (ECM); allow stem cell viability and differentiation; and have high porosity, which provides greater cell infiltration compared to 2D scaffolds. Finally, we found that, in industrial applications of wet electrospinning: (1) additives improve the performance of pure polymers; (2) the concentration of the solution influences porosity and fiber packing; (3) flow rate, voltage, and distance modify fiber morphology; (4) the surface tension of the non-solvent coagulant on which the fibers are deposited has an effect on their porosity, compaction, and mechanical properties; and (5) deposition time defines scaffold thickness.

Keywords: Wet electrospinning, Electrospinning, Wet spinning, Scaffolds.

Resumen

En el electrospinning húmedo, se deposita una solución de polímero natural o sintético sobre un coagulante líquido no disolvente utilizado como colector. Esta técnica puede crear andamios de nanofibras en 3D con mejores propiedades (por ejemplo, porosidad y alta superficie) que las de los andamios tradicionales en 2D producidos por electrospinning estándar. Gracias a estas características, el electrospinning húmedo puede emplearse en una amplia gama de aplicaciones industriales y de ingeniería de tejidos. Esta revisión pretende ampliar el panorama de esta técnica, sus posibles campos de actuación y su gama de materiales habituales. Además, también se discuten sus tendencias futuras. En este estudio, revisamos los artículos sobre este método publicados entre 2017 y 2021 para establecer el estado del arte del electrospinning húmedo y sus aplicaciones más importantes en ingeniería de tejidos cardíacos, cartilaginosos, hepáticos, apósitos para heridas, cutáneos, neuronales, óseos y musculares esqueléticos. Adicionalmente, examinamos sus aplicaciones industriales en la purificación del agua, los filtros de aire, la energía, los sensores biomédicos y los textiles. Los principales resultados de esta revisión indican que los andamios 3D para aplicaciones de ingeniería tisular son biocompatibles; imitan la matriz extracelular (MEC); permiten la viabilidad y diferenciación de las células madre; y tienen una alta porosidad, lo que proporciona una mayor infiltración celular en comparación con los andamios 2D. Por último, descubrimos que, en las aplicaciones industriales del electrospinning húmedo: (1) los aditivos mejoran el rendimiento de los polímeros puros; (2) la concentración de la solución influye en la porosidad y el empaquetamiento de las fibras; (3) la velocidad de flujo, el voltaje y la distancia modifican la morfología de las fibras; (4) la tensión superficial del coagulante no solvente sobre el que se depositan las fibras tiene un efecto sobre su porosidad, compactación y propiedades mecánicas; y (5) el tiempo de deposición define el espesor del andamio.

Palabras clave: Electrohilado en húmedo, Electrohilado, Hilado en húmedo, Andamios.

1. INTRODUCTION

Scaffolds are composed by nanofibers, they have different topographic characteristics such as high porosity, large surface area per unit mass (for example, nanofibers with 100 nm in diameter have a specific surface area of 1000 m2/g), high permeability, as well as the ability to mimic the extracellular matrix (ECM) of tissues both chemically and mechanically [

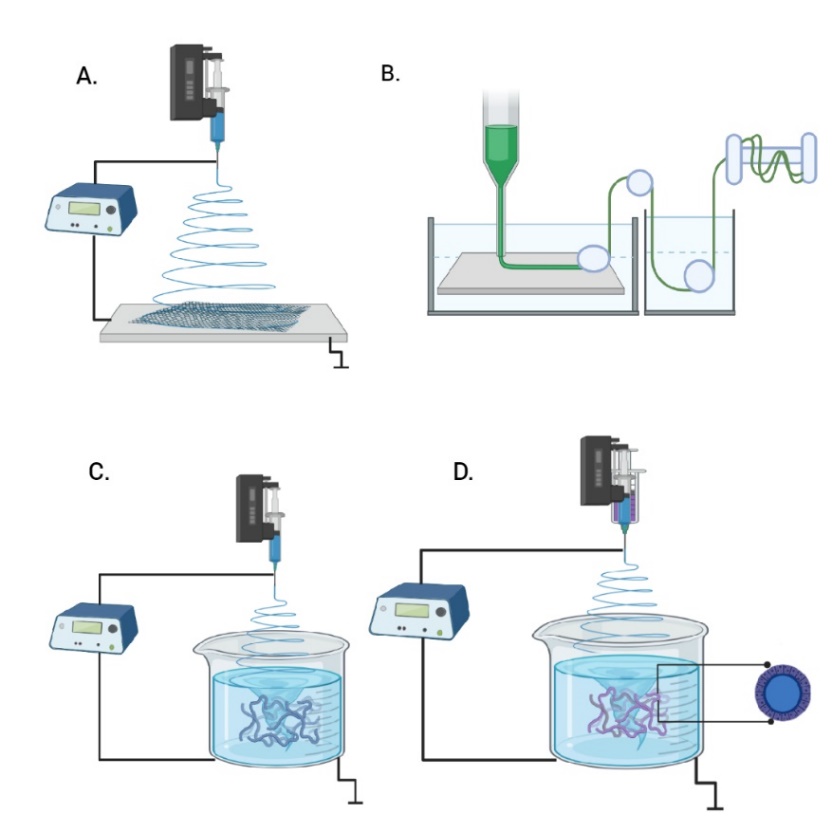

Electrospinning (Figure 1A), is a method to produce 2D or 3D nanofibers, from a natural or synthetic polymer solution, where a high voltage is applied to generate aligned or random fibers with diameters from nanometers to micrometers [

Electrospinning allows to create nanofibers with diameters below 500 nm [

A brief history of electrospinning technique, Anton Formhals filed several patents between the years 1934 and 1944, the first patent in the United States that described the electrospinning operation in 1934, to produce cellulose acetate filaments using an electrostatic force of 57 kV and in 1944 he reported a patent with improvements towards the commercialization of electrospinning, in the mobile collector to collect textile yarns in a stretched condition, such as that of a rotating drum in conventional spinning [

Despite these early discoveries, the process was not used commercially with great success until the early 1990s, when the term "electrospinning" was coined from the previously used term "electrostatic spinning". Around 30 patents were issued on the electrospinning technique, gaining popularity thanks to a growing interest in nanotechnology and due to improvements in characterization techniques and the ability to manufacture complex scaffolds. In 1996, Reneker and Chun demonstrated the manufacture of nanofibers from various polymers applied to different areas of science and industry [

Some current applications of electrospinning are in biomedical areas as tissue engineering, drug delivery, wound dressings, catalyst, and enzyme carriers. Industrial applications such as cosmetics, composite reinforcement, air filter, affinity membranes and recovery of metal ions in water, smart textiles and protective clothing, battery /cell capacitor, sensor, catalyst [

The traditional electrospinning apparatus had been modified to explore new possibilities and improve the nanofiber properties, because 2D scaffolds show insufficient cellular infiltration and high packing density. Other techniques derived from electrospinning have been needleless electrospinning [

Wet spinning, (Figure 1B) is the oldest textile technique used to produce synthetic polymeric fibers, such as nylon (polyamide), spandex, rayon, aramid, and acrylic. It is based on an extrusion with the air of a very viscous polymer solution directly into a coagulation bath usually cold water or in an organic solvent, or in a weak inorganic acid, to form a filament emerge from the solution, then, they stretch and solidifies as continuous fiber with a final diameter on the order of micrometers, these fibers are washed, dried and finally collected in a rotor [

Currently, Russia and China, produce fine linen threads.

Wet electrospinning emerged as a combination of electrospinning and wet spinning for the laboratory-level production of 3D structure of nanofibrous (Figure 1C). This technique consists of a polymeric solution within a syringe connected to a pump, that ejects with a flow rate programmed the solution and with high voltage it creates fibers. These are immersed in a coagulation bath as a collector. The liquid bath consists of a non-solvent for the polymer solution (such as methanol, ethanol), are commonly used due to their low surface energy. In this coagulation bath, the solution solidifies to form long fibers with diameters between 30 to 600 μm, depending on the needle diameter, polymer composition, and flow rate [

Nevertheless, an additional molding and freeze-dried process after wet electrospinning is usually required to retain the 3D shape [

The high pore size of 3D scaffolds, development by wet electrospinning varies among 250-500 μm, measured by Branauer Emmet Teller (BET) porosimetry (gas absorption) or by processing micrograph images in software such as Image J, this characteristic allow improves cell adhesion, infiltration, and proliferation inside of the scaffolds for tissue engineering applications, in compared with 2D scaffolds which exhibit smaller pores [

Polymers with low viscosity that cannot be spun by other procedures, it can be used by wet electrospinning to create fibrous scaffolds [

Coaxial configuration of syringes (Figure 1D) has been used for loaded drug, encapsulation, and drug delivery in wet electrospinning in a core–shell structure of bioactive compounds, including antibiotics, proteins, growth factors and genes [

Wet electrospinning also known as wet electrospun, dry-wet electrospinning, liquid assisted electrospinning and immersion electrospinning (I-ESP), was first described by Yang, W et.al. 2005 of Donghua University, China, which created ultrafine Poly (m-phenylene isophthalamide (PMIA) fibers in water as ionic liquid [

In our knowledge, a few authors have reviewed the wet electrospinning technique, Puppi et. al. 2017, presented a mini-review where explain how wet electrospinning can be modified by computer and could be used to additive manufacture (AM), to expand their productivity from lab scale to industrial scale [

2. WET ELECTROSPINNING APPLICATIONS

Wet electrospinning has applications in cardiac, cartilage, hepatic, wound dressings, and skin tissue, neural, bone, and skeletal muscle for tissue engineering, as well as other industrial applications such as water purification and air filter, biomedical sensors and flame retardants.

2.1 Tissue engineering

Tissue engineering for regenerative medicine aims to develop scaffolds from natural or synthetic polymer biomaterials, this discipline emphasizes the critical role of structure and biomechanics in scaffolds to seed cells and use growth factors, and then with this graft replacement different organs. 3D scaffolds are biocompatible, biodegradable, and biomimetic extracellular matrix (ECM) of natural tissues and its presets macro porous allows differentiation and proliferation of cells inside scaffolds, without the steric hindrance of cell motility and provides structural support similar to tissue objective [

2.1.1 Cardiac or soft tissue engineering

Wet electrospinning has been used to create soft tissue engineering 3D scaffolds, these must possess good mechanical properties, to support cardiomyocytes and stem cells functions.

The ideal polymers for this application are biodegradable, with structural stability and thermoplastic elastomers, with elastic modulus (E) in the range 0.1–100 MPa, these must be biomimetic depending on the cardiac tissue to be replaced, which enable them to maintain their integrity to endure cyclic deformation and to transfer mechanical stress similar to cardiac muscle and blood vessels, while it allows cell growth [

| Polymer | Solvent | Electrospinning processing parameters | Fiber diameter | Porosity | Main outcomes | |||

| Voltage | Flow rate | Distance | Collector | |||||

| PBS-DLS 20 % w/v | Chloroform: Methanol | 15 kV | 7 mL/h | 23 cm | Methanol | 9.9 µm | 250 nm | L929 proliferation [ |

| PLGA 8 % w/v | Chloroform: Dimethyl- formamide | 18 kV | 0.5 mL/h | 4 cm | Isopropyl alcohol/ distilled water | (0.9 ± 0.4) µm | (18 ± 5) µm | Human stem cells viability [ |

| Alginate / PEO 2, 4, 5 % w/v / gelatin hydrogel | Deionized water | 7 kV | 0.1 mL/h | 7 cm | Water: Ethanol | 360 nm | -- | Human hiPSC attachment [ |

| Cellulose 2 % and 3 % w/v Ibuprofen 6 % wt | [BMIM]C | 10kV | -- | 12cm | Water | 1-20 µm | -- | Cell viability greater than 80% [ |

Sonseca et. al. 2020, developed architectures of 3D helically coiled scaffolds (HCS) from segmented co-polyester of poly (butylene succinate-co-dilinoleic succinate) (PBS-DLS) (70:30) at 20 % w/v in the solvent chloroform-methanol (7:3) vol, and for the coagulant solution they used (water, ethanol, and methanol), with surface tension (72.86, 22.10, 22.50 mN/m, respectively). In water, the scaffolds floated and formed a 2D structure. Whereas scaffolds in ethanol and methanol show no difference in the morphology. The authors affirm that, the low surface tension in coagulant solution allows a low packaged structure and avoid the fibers from accumulating upwards. By adjusting the wet electrospinning parameters, such as flow rate and voltage, different diameters, and morphologies, flat ribbon-like and coil-like fibers similar to heart perimysium, can be obtained. It was found that, 3D scaffolds have more open pores, better mechanical properties and show 2 times higher proliferation than 2D scaffolds.

The scaffolds were evaluated by seeding L929 murine fibroblasts, which showed no cytotoxicity [

Krishnamoorthi et. al. 2020, fabricated a 3D scaffold of Poly lactide-co-glycolide (PLGA) at 8 % w/v in chloroform: dimethylformamide (7:3) vol, as a solvent, and isopropyl alcohol/ distilled water (7:3) ratio, as coagulant, and 0.05 % F108 surfactant to reduce the surface tension of water. This scaffold induced spontaneous differentiation of human stem cells, maintained viability, the authors highlight the importance of bioactivity in the scaffolds to resemble the extracellular matrix and allow the differentiation of stem cells from cardiac tissue and the measurement of proteins and specific markers that indicate the formation of new tissue [

Majidi et. al. 2018, fabricated a 3D scaffold macroporous, sodium alginate (Mw = 396 kDa)/poly (ethylene oxide) (PEO) (Mw = 900 kDa) at 2, 4, 5 % w/v, and gelatin from cold water fish skin hydrogel (Mw = 60 kDa), in deionized water as a solvent, and they used water: ethanol (1:5) ratio, as coagulant with 2 % w/v of calcium chloride and Pluronic F-127 surfactant, scaffold was freeze-drying. The authors indicated the requirement of a convergence between biological needs and the development of biomaterials that meet these requirements, for example 3D scaffolds mimic the extracellular matrix and in future works it is expected that a total integration with the native tissue can be achieved. The use of the Pluronic F-127 surfactant allows to reduce the surface tension of the water, improving the electrospinning of the alginate, the calcium chloride improved the coagulation and the morphology of the fibers, the low surface tension of the ethanol helped to create a macroporous and fiber structure not compact. Due to the macropores, the scaffolds improved the adhesion in human IPSC-derived ventricular cardio myocytes [

Liu et. al. 2017, fabricated scaffolds of Raw pulpis with 87 % alpha-cellulose 2 % and 3 % w/v, with ibuprofen 6 % wt, in 1-Butyl-3-methylimidazolium chloride [BMIM]C as a solvent, and water as coagulant, scaffolds were cultured with mouse HL-1 cardio myocytes, and these substrates exhibited cellular viability, the authors performed an analysis of the morphology of the fibers with respect to the concentration of the cellulose at 2 % wt some fibers were fused, while at 3 % wt the areas of fiber fusion disappeared, the ibuprofen remained distributed on the surface from the scaffold or trapped within its pores [

2.1.2 Cartilage tissue engineering

Cartilage has limited self-repair due to lack of blood or nerve supply and the low proliferation rate of chondrocytes [

Natural polymers can be blended with synthetic polymers to improve mechanical strength, porous scaffolds are better for chondrocyte infiltration [

The use of hydrogels is popular due to their similarity between its hydrated structures and the hydrophilic environment of the cartilaginous ECM, new approach is about the combination of hydrogels with fibers as reinforcement that improves tensile strength [

Li et. al. 2020, developed a meniscus substitute by wet electrospinning with fibroin of Bombyx mori cocoons, polycaprolactone (PCL) (Mw: 80 kDa) (1:4) ratio, and strontium chloride (SrCl.) (20 mmol/L) in hexafluoro isopropanol (HFIP) and water (90:10) as solvent, collected in 7 ml of anhydrous ethanol as coagulant, their pore size varied between (10-20 μm) and mechanical support (61.6 ± 2.9) MPa for traction and (0.11 ± 0.03) MPa for compression). The addition of Sr to the meniscus 3D scaffold strongly stimulated ECM formation in vitro, enabled type II collagen expression and attenuated cartilage degeneration in a rabbit model with meniscectomy. The thickness of the scaffold was regulated by adjusting the deposition time and the pore size was regulated by the concentration of the solution. In future work, the authors propose to add chemo-attractants or growth factors to the scaffolds for functional regeneration of the meniscus and to delay the development of osteoarthritis [

Rafiei et.al. 2020, prepared the protein bovine serum albumin (BSA) 10 mg/ml with distilled water as solvent, and PCL (Mw: 80.000 Da) 10-15 % w/v with chloroform/ dimethylformamide (DMF) 70:30 v/ v as solvent, collected in water/ ethanol (1:9 v/v) as coagulant in a beaker of 3 cm deep, by coaxial wet electrospinning to develop 3D scaffolds with a core-shell structure for cartilage tissue replacement. The high viscosity of the PCL solution, coaxial needle gauge and applied voltage produced relatively large fiber diameters.

The porosity of 3D scaffolds could be controlled by density, hence by compression. By increasing the compaction of the scaffolds by decreasing the pore size, which causes the Young's modulus to increase (0.3-5 MPa). Scaffold was biocompatible with human fibroblast cells [

Gunes et. al. 2020, fabricated 3D multi-layered scaffolds of poly (3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) (Mw: 80 kDa) at 3 % w/v, and Benzyl triethylammonium chloride (BTEAC) 0.2 % w/v, with chloroform as solvent, collected in ethanol-distilled water mixture at (9:1) volume ratio and carboxymethyl chitosan (CMC) - fibroin of Bombyx mori cocoons hydrogel. The scaffolds mimicked the hydrated ECM structure of cartilage through an interconnected microporous structure, increased compressive strength (207 +/- 45 kPa), that resulted good cartilage substitute due to promotes chondrogenic differentiation of bone marrow mesenchymal stem cells (BMSCs) [

| Polymer | Solvent | Electrospinning processing parameters | Fiber diameter | Porosity | Main outcomes | |||

| Voltage | Flow rate | Distance | Collector | |||||

| Fibroin, PCL, SrCl2 | HFIP/water | 12 kV | 0.8 mL/h | 15 cm | Ethanol | 400-600 nm | 100–200 μm | Expression of the collagen II gene [ |

| PCL /BSA | Chloroform /DMF for PCL, water for BSA | 7-12 kV | Shell:3 mL/h Core:1 mL/h | 7 cm | Water/ ethanol | (8 ± 1.6) μm | (105 ± 90) μm | Biocompatible with Human fibroblast cells [ |

| PHBV 3 % w/v and BTEAC 0.2 % w/v and CMC- fibroin hydrogel | Chloroform | 20 kV | 2.0 mL/h | 10 cm | Ethanol-distilled water | 731 nm | -- | Chondrogenic differentiation of BMSCs [ |

2.1.3 Hepatic tissue engineering

Due to the few liver donors, the development of 3D grafts that can maintain the functionality and viability of the hepatocytes has been promoted due to their similarity of random fibers and porosity with the extracellular matrix of the liver. Proteins such as collagen I and fibronectin present in the natural microenvironment enable the functions and interactions of hepatocytes, gene expression, and cell phenotype [

| Polymer | Solvent | Electrospinning processing parameters | Fiber diameter | Porosity | Main outcomes | |||

| Voltage | Flow rate | Distance | Collector | |||||

| PLGA | Chloroform/ DMF | 18 kV | 0,5 mL/h | 4 cm | Isopropyl alcohol and deionized water | (0.91 ± 0.45) μm | (30.03 ± 8.86) μm | Efficient chemisorption on the 3D scaffolds [ |

| PLGA with collagen type I | Chloroform/DMF | 18 kV | 0,5 mL/h | -- | Isopropyl alcohol and deionized water | (870 ± 300) nm | (27.5 ± 7.5) µm | 10-fold greater albumin secretion [ |

Das et. al. 2020, fabricated 3D scaffolds highly porous of poly (lactic-co-glycolic acid) (PLGA) (80:20) with chloroform: dimethylformamide (DMF) (7:3) ratio as solvent, collected in isopropyl alcohol and deionized water 7:3 (v: v) as coagulant. Scaffold was modified with collagen-I and plasma fibronectin (3:1) ratio. Protein-containing scaffolds showed better Huh75 cell viability, improved the cell microenvironment, provided efficient chemisorption, and increased the albumin secretion and CYP3A4 - CYP3A7 expression in 28 days of culture [

Brown et. al. 2018, developed a 3D scaffold of poly (L-lactide-co-glycolide) (PLGA) with chloroform: dimethylformamide (DMF) (7:3) ratio as solvent, collected in isopropyl alcohol and deionized water 7:3 (v: v), with 0.05 % wt Pluronic F-108 used as surfactant. Scaffold was modified with collagen type I. 3D scaffold was cultured per 2 weeks with primary human hepatocytes, this guide 10 times more secretion of albumin and increase the transcription of hepatocyte specific CYP450 genes (CYP3A4, 3.5 times and CYP2C9, 3 times) in comparing to scaffolds without protein treatment. Wet electrospinning produces scaffolds with larger pore size compared to traditional electrospinning which enables incorporation of hepatocytes into the matrix [

2.1.4 Wound dressings and skin tissue engineering

Chronic wounds represent a problem due to these could not cicatrize and the closure of these is not achieved, which can cause infections. An ideal scaffold should imitate the natural ECM, providing signage to cells and growth factors to the site of injury and cover the wound bed, which facilitates angiogenesis, collagen deposition and granulation tissue formation, while improving the healing process [

and skin tissue engineering. Source: Authors

| Polymer | Solvent | Electrospinning processing parameters | Fiber diameter | Porosity | Main outcomes | |||

| Voltage | Flow rate | Distance | Collector | |||||

| PCL 10 % wt | DCM / DMF | 10 kV | 40 μl/min | 40 mm | Ethanol/water | 120 µm at drawing speed of 0.2 m/s | -- | Cell attachment of Human Umbilical Vein Endothelial Cells (HUVECs) [ |

| Sericine/ gelatine PLGA NPs with heparin | Acetic Acid and DMSO | 20 kV | 2 mL/h | 10 cm | Ethanol | 100 nm | -- | Cell viability of fibroblast L929 [ |

| PCL 12 % wt | Chloroform: DMF | 18 kV | 0.5 mL/h | 18 cm | Ethanol | 0.54 µm | 95.3 % | Migration into scaffold of fibroblast cells [ |

| PLA 15 % (w/v) | Chloroform | 18kV | 3,8 mL/h | 10cm | Aqueous (NaOH) | (2.74 ± 0.76) µm | -- | Viability of rat bone-marrow stem cells (BMSCs) [ |

| PVA 6 % w/v /Cs 3 % w/v | Water Acetic acid in deionized water 2:1 (v/v) | 13-15 kV | 1 mL/h | 8 cm | Water bath 200 mL containing 12 g of Aloe Vera | (1136.50 ± 892.45) nm | -- | Scaffold non- toxic to L929 fibroblast [ |

| PCL RCSC (1:1) ratio. | HFIP | 1.3 - 1.5 kV/cm | 1 mL/h | 5 mm | Ag NPs solution in ethanol | (5.819 ± 1.867) µm | 90 % | Antibacterial properties, minimum cytotoxicity on human fibroblast [ |

Jiang et. al. 2021, fabricated sandwich scaffold of polycaprolactone (PCL) (Mw: 80.000 Da), with Dichloromethane (DCM): Dimethylformamide (DMF) (2:1) (v: v) as solvent, collected in ethanol/water as coagulant. Differences in the surface tension of water (72.8 mN/m) and ethanol (22.1 mN/m) produced fibers with different characteristics. Due to the high surface tension of water, the net-like fibers cannot break the hydrogen bond at the water surface and floated, they broke easily when pulled out of the water, due to the high adhesive force between the water molecules and the fibers. The fibers formed a yarn structure, immersed in the ethanol and formed into a continuous bundle upon removal from the ethanol bath. When the ethanol/water ratio was less than (28.52 mN/m), a continuous fiber bundle was obtained. Scaffold was inspired in crochet textile technique to imitate collagen porous fibers, using wet electrospinning with drawing modification in coagulation bath. It allows to obtain different nanofibers diameter according to their drawing speed, this sandwich morphology allowed cell attachment of Human Umbilical Vein Endothelial Cells (HUVECs) [

Akolpoğlu Başaran et. al. 2021, development 3D scaffold of sericine/Type A gelatin (1⁄2 v: v) (20 % wt) with acetic acid and dimethyl sulfoxide (DMSO) as solvent, collected in ethanol as coagulant. 3D scaffolds were supplemented with PLGA (Mw:7–14 kDa) nanoparticles loaded with heparin, the cell viability of fibroblast L929 increased with the content of heparin at 72 hours of in vitro culture. The presence of higher serine-containing nanoparticles in the scaffold significantly increased the proliferation of L929 cells by the fifth day of incubation. Heparin stimulates fibroblast cell proliferation. The authors emphasize the need for further investigation of the wound healing/skin regeneration potential of the produced materials [

Jing et. al. 2019, developed scaffolds of Polycaprolactone (PCL) (Mw: 80.000 g/mol) 12 % wt, with chloroform: Dimethylformamide (DMF) (6:4) as solvent, collected in ethanol bath as coagulant saturated with carbon dioxide (CO.) and introduced into a water bath, in which they expanded due to the escape of CO.. The porosity of the 3D scaffold was 95.3 %, much higher than that of the 2D scaffold. The 3D scaffold mimicked the ECM through porosity and surface area and favored the growth of 3T3 human fibroblasts, with enhanced cell adhesion and increased cell viability [

Ghorbani et. al. 2018, prepared 3D high porous scaffolds of polylactic acid (PLA) (Mw: 160.000 Da) 15 % (w/v) with chloroform as solvent, collected in aqueous solution of sodium hydroxide (NaOH, pH 13) as coagulant. 3D scaffolds of PLA highly porous with a high surface area allows appropriate gas exchange and exudate absorption. The in vitro and in vivo results suggest that PLA 3D scaffold seeded with rat bone-marrow derived mesenchymal stem cells (BMSCs), was nontoxic and biocompatible for wound repair [

Naseri-Nosar et. al. 2017, developed a 3D scaffold by wet electrospinning of recombinant human erythropoietin/aloe Vera gel–releasing polyvinyl alcohol (PVA) 6 % w/v in water /Chitosan (Cs) 3 % w/v in acetic acid in deionized water 2:1 (v/v), collected in water bath 200 mL containing 12 g of Aloe Vera. Aloe Vera has anti-inflammatory and immunomodulatory effects on wound healing. It also increases fibroblast growth and activity and increases the level of collagen in the wound. In addition, it increases the content of hyaluronic acid and dermatan sulfate in the granulation tissue. RhEpo caused considerable angiogenesis in the treated wounds, accelerated re-epithelialization and shortened wound inflammation. 3D scaffold was not toxic with L929 fibroblasts and improved the wound healing in Wistar rats in comparing with sterile gauze [

Zhang et. al. 2017, fabricated 3D scaffold by wet electrospinning with ranachensinensis skin collagen (RCSC) and polycaprolactone (PCL) (Mw:52.000 Da) 10 % wt (1:1) ratio in 1,1,1,3,3,3, -hexafluoro-2- propanol (HFIP) as solvent, collected in silver nanoparticles (Ag NPs) solution in ethanol 25 mg/L, 50 mg/L, 75 mg/L, and 100 mg/L. By increasing the concentration of the silver nanoparticles, the uniformity of the fibers was reduced, generating larger fiber diameters and increased pore sizes. 3D scaffolds had a porosity of 90 %, reinforces antibacterial properties and present minimum cytotoxicity in human fibroblast [

2.1.5 Neural tissue engineering

Nerve injuries caused by physical trauma, diseases as Alzheimer, Huntington, Parkinson spinal muscular atrophy (SMA), or genetic problems, result in the loss of motor and sensory functions, which causes disability. The objective of neural tissue engineering is to repair and to conduct of guide the neural alienation, further direct axonal extension, and neural growth.

By manufacturing 3D cylindrical scaffolds from biodegradable and biocompatible polymers that create an environment that mimetic the structure and components of autologous nerve [

| Polymer | Solvent | Electrospinning processing parameters | Fiber diameter | Porosity | Main outcomes | |||

| Voltage | Flow rate | Distance | Collector | |||||

| PCL 13 % (w/v) | TFE | 15 kV | 1 mL/h | 15 cm | Water | (543 ± 267) nm | -- | Cell differentiation of ReNcell® VM human [ |

| PLGA 10 % wt | Chloroform: DMF 7:3 | 10 kV | 0.8 mL/h | 10 cm | Ethanol | (1.96 ± 0.16) µm | (35.04 ± 21.09) µm | Differentiation of IPSC derived neurons in 7 days of culture [ |

| PCL/SF/CNTs | HFIP | 12 kV | 1 mL/h | -- | Distilled water/ ethanol | 25, 50, 100 µm | -- | Aligned nanofibrous structure induced PC12 cells extension [ |

| PLA 10, 13, 15, 17, 20 % w/v Gelatin, alginate | Chloroform | 18 kV | 3.8 mL/h | 10 cm | Sodium hydroxide (NaOH) | -- | (82.5 ± 1.9) % | Differentiation of human Wharton Jelly into neuron cells [ |

| Cellulose acetate and gelatin 8% w/v | Acetic acid glutaraldehyde 25% (w/v) | 20 kV | 30.40 mL/h | 15 cm | Water/ethanol gabapentin (GBP) | (1.78 ± 0.89) µm. | (75.83 ± 1.76) % | Biocompatible with primary rat Schwann cells (SCs) [ |

| PLA 10 % wt,/ CA 8 % wt. / CGNs | Core: PLA in 1, 4-dioxane Shell: CA in acetone | 18 kV | 1 mL/h | 10 cm | Water | (945.00 ± 479.97) nm | 60% | Biocompatible with Primary rat Schwann cells (SCs), to support their regeneration [ |

| PANI/ PLGA 3 % w/v PCL | Chloroform: dimethylformamide (70:30) | 20 kV | 1 mL/h | 15 cm | Water | (770±166.6) µm | 1.3-10 µm | Human glioblastoma cell proliferation [ |

Garrudo et. al. 2021, achieved differentiation of REN-VM cell into neural cells (neurons and astrocytes) on polycaprolactone (PCL) (Mw: 80.000 Da) 13 % (w/v) with trifluoroethanol (TFE) as solvent, collected in water as coagulant. 3D scaffolds with glycosaminoglycans (GAG), as hyaluronic acid (HA), chondroitin sulfate and heparan sulfate, allows the creation of complex structures ECM, such as peripheral networks. Improving the design of electroconductive scaffolds for neural tissue engineering applications. Disease mechanisms can be studied, and new drugs tested, for the development of implants for transplantation in patients with neurological diseases [

Ranjan et. al.2020, encapsulated pluripotent stem cell (IPSC) in 3D scaffold of poly (lactic-co-glycolic acid) (PLGA) 10 % wt with chloroform: dimethylformamide (DMF) 7:3 ratio as solvent, collected in ethanol. Although, 3D scaffold reduced cell proliferation, accelerates neuronal differentiation. The ethanol bath increased the dispersion of the fibers and reduced their binding. Pore size decreased with increasing solution concentration. The scaffolds had large, interconnected pores with lower fiber packing densities compared to 2D fiber mats, which allowed cells to easily infiltrate inside them [

Wang et. al. 2019, developed a 3D scaffold of polycaprolactone (PCL) (Mw: 80.000 Da), silk fibroin (SF), and carbon nanotubes (CNTs) (8:2:0.1 ratio) with hexafluoro isopropanol (HFIP) as solvent, collected in distilled water/ ethanol (8:2 v/v) as coagulant. The 3D scaffolds exhibited biocompatibility with PC12 cells, provided a suitable microenvironment for improved alignment and extension, hydrogel shell mimicking the epineuron layer protected their organization [

Ghorbani et. al. 2018, seeded human Wharton jelly-derived mesenchymal stem cells on 3D conductive scaffolds of polylactic acid (PLA) 10, 13, 15, 17, 20 % w/v with chloroform as solvent, collected in Sodium hydroxide (NaOH) and coated with natural polymers including alginate and gelatin, followed by a multi-wall carbon nanotube (MWCNT) coating, this scaffold supported the growth and improvement hMSCs cell differentiation, they expressed neuronal markers: Nestin and Neuro-D1 [

Farzamfar et. al. 2018, produced 3D scaffold of cellulose acetate (CA) and gelatin (Gel) 1:1 ratio, 8 % w/v with acetic acid and glutaraldehyde 25 % (w/v) as solvent, collected in water/ethanol (3:7) v/v and gabapentin (GBP) 3, 6, 12 % w/v. Scaffold shown to be compatible with Primary rat Schwann cells (SCs), in the in vivo study the scaffold obtained from 6 % (w/v) GBP enhanced the regeneration of created injury in a sciatic nerve defect model in Wistar rats [

Naseri-Nosar et. al. 2017, developed a biodegradable 3D drug-loaded scaffolds with the core-shell structure with polylactic acid (PLA) 10 % wt was dissolved in 1, 4-dioxane as core /cellulose acetate (CA) 8 % wt was dissolved in acetone as shell / citalopram-loaded gelatin nanocarriers (CGNs), 3D scaffolds was collected in water as coagulant, they shown biodegradability and cytocompatibility with rat Schwann cells, in vivo study in a sciatic nerve defect revealed that scaffolding with citalopram enhanced lesion regeneration [

Zamani et. al. 2017, fabricates electrical excitable 3D scaffolds of polyaniline (PANI) (Mw: 50.000 Da)/ poly (lactic-co-glycolic acid) (PLGA) 3 % (w/v) and polycaprolactone (PCL)(Mw: 80.000 Da) scaffolds with chloroform: dimethylformamide (70:30) as solvent, collected in water as coagulant, 3D scaffolds were biocompatible and effective to electrical stimulation The authors emphasize that future study will focus on functional conductive scaffolds in the presence of electrical stimulation in nerve cells. 3D scaffold was effective to promote A-172 cell proliferation for spinal cord regeneration [

2.1.6 Bone tissue engineering

Bone tissue engineering aim is to repair or replace lost large bone tissues caused by trauma or disease. By the use of scaffolds with the properties, porous, biocompatible, bioactive, biodegradable, high mechanical strength, sufficient to make it structurally stable for the formation of new tissue, and mimic the bone extracellular matrix (ECM), that provides the microenvironment for cell attachment, also, the use of bioactive agents promote cell migration, proliferation, differentiation, diffusion of oxygen and nutrients, this together produces new tissue formation and thus bone regeneration [

| Polymer | Solvent | Electrospinning processing parameters | Fiber diameter | Porosity | Main outcomes | |||

| Voltage | Flow rate | Distance | Collector | |||||

| Core: PCL / shell: cellulose | MC, DMF | 5,5 kV | 0,9 mL/h | 1 cm | Ethanol | 10 % wt: (9.7 ± 2.3) μm 15 % wt: (22.6 ± 2.6) μm 20 % wt: 50∼80 μm | 400 µm | Promotes osteogenic activities, using MG63 cells [ |

| PCL, gelatin, P-188 | HFIP | CW: 17kV CE: 12 kV | CW: 2 mL/h CE: 4 mL/h | CW: 15 cm CE: 15 cm | CW: Water CE: Ethanol | CW: (2.15 ± 0.46) µm, CE: (3.34 ± 0.80) µm | CW: 20–200 µm CE: 4–240 µm | Viability and ALP activity for Saos-2 cells [ |

| PHBV 3 % w/v | Chloroform | 20 kV | 2 mL/h | 10 cm | Ethanol- water (9:1 v:v) | PHBV: (552 ±70) nm Fish scale/PHBV: (560 ± 64) nm | PHBV: 84 % Fish scale/PHBV: 81.9 % | Improved the biomineralization and MG-63 cell viability [ |

| PHBV /PCL | HFIP | 8-9 kV | 4 mL/h | 12cm | Ethanol | PHBV/PCL: (1.38 ± 0.2) µm, PHBV/PCL/DS: (2.47 ± 0.5) µm | PHBV/PCL: 75.85 %, PHBV/PCL/DS: 58.47 % | Cell viability of Saos-2 cell improves with the addition of diatom shells (DS) [ |

| Collagen/PEO/PVA 2:1:1 | Acetic acid | 8 kV | 0.06 mL/h | 50 mm | Ethanol | (293.8 ± 49.2) μm | (413.9 ± 40.3) μm | Stem cells viability, and biocompatibility [ |

| P3HB 5 % w/v, PBA 10 % w/v | Chloroform | 15 kV | 1 mL/h | 16.5 cm | Ethanol | (5.08 ± 1.57) µm | -- | Cell attachment and proliferation of MC3T3-E1 mouse pre-osteoblastic [62] |

| PHBV, BTEAC, Fibroin HAp | Chloroform | 20 kV | 2 mL/h | 10 cm | Ethanol-water | 450–850 nm | 80 – 85 % | Cell viability of MG-63 osteosarcoma human cells [ |

Choe et. al. 2020, fabricated a 3D scaffold by bioprinting and wet electrospinning using Core: polycaprolactone (PCL) (Mw: 80.000 g/mol) dissolved in methylene chloride (MC) /Shell: cellulose acetate (Mw: 30.000 g/mol) dissolved in dimethylformamide (DMF), collected in ethanol. The distance between the nozzle and the collector and the concentration of the solutions determined the effect of the coil structure and the homogeneity of the cellulose. 3D scaffold was evaluated in vitro using MG 63 cells showed osteogenic activities (ALP activity, calcium deposition, and gene expression) [

Alissa Alam et. al. 2020, produced polycaprolactone (PCL) (Mw: 70.000-90.000 Da)/ gelatin from porcine skin/ Poloxamer 188 scaffolds with Hexafluoro-2-propanolol (HFIP) as solvent, collected in water/ethanol. Ethanol-deposited scaffolds exhibited larger fiber diameter, with better mechanical properties and higher thickness compared to water-collected scaffolds. As future work the authors highlight the need to optimize coaxial wet electrospinning to produce scaffolds that can release both hydrophilic and hydrophobic bioactive agents with improved osteogenic properties. Scaffold presented controlled release the protein (Beta-lactoglobulin) and vitamin K2, additionally, enhanced Saos-2 cell viability and ALP activity [

Kara et. al. 2020, produced 3D nanofibrous fish scale/poly (3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) (Mw: 80.000 Da) 3 % w/v, including an organic soluble salt BTEAC 0.2 % w/v dissolved in chloroform, collected in ethanol- water (9:1 v: v) as coagulant. The incorporation of fish scales into the PHBV scaffold increased biomineralization the deposition of Ca-P minerals, as well as the compressive modulus and higher bioactivity, MG-63 cell viability, alkaline phosphatase activity, and type I collagen production [

Dalgic et. al. 2019, produced 3D fibrous scaffold by co-electrospinning of poly (hydroxybutyrate-co-hydroxy valerate) (PHBV) / poly (ε-caprolactone) (Mw:80.000 Da) (PCL) 7/3 wt/wt at 14 % wt, with Diatom shells (DS), dissolved in Hexafluoro-2-propanol (HFIP), collected in ethanol as coagulant. In vitro studies showed that scaffolds bearing diatom shells (DS) a natural source for silicon, it was used as a doping agent that improved cell viability and proliferation of human osteosarcoma (Saos-2), additionally, showed osteocompatibility, alkaline phosphatase activity, and osteocalcin synthesis, osteogenic bioactivity [

Kim et. al. 2019, developed 3D scaffold of collagen type-I, extracted from porcine skin /PEO (Mw: ~900.000 g/mol) /PVA (Mw: 89.000 – 98.000 g/mol) in acetic acid as solvent, it was immersed in 1-ethyl-(3–3-dimethylaminopropyl) (EDC). The bone marrow-derived mesenchymal stem cells were cultured on the scaffold for 1 and 3 days, and exhibit cell viability and biocompatibility, the fibrous collagen structure provided a suitable microenvironmental condition to produce cell-substrate interactions [

Çatıker et. al. 2019, obtained porous 3D matrices via lyophilization and wet electrospinning of poly(3-hydroxybutyrate) (P3HB) (5 %, w/v) in chloroform as solvent, collected in ethanol as coagulant. Scaffold was reinforced with Poly-β-alanine (PβA), it demonstrated better cell attachment of MC3T3-E1 mouse pre-osteoblastic cell and proliferation compared to pure P3HB scaffolds, the addition of PBA had a positive impact on mechanical properties, such as elasticity, due to the decrease in crystallinity [

Colpankan Gunes et. al. 2019, prepared by wet electrospinning 3D scaffold of silk fibroin (0.5 % (w/v)) with poly (3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) (Mw: 80.000 Da) (3 % (w/v)) and benzyl triethylammonium chloride (BTEAC) (0.2 % (w/v)) in chloroform as solvent, with hydroxyapatite (HAp) 0.3 % (w/v), ethanol-water (9:1 v: v) was used to collect the nanofibers. In vitro cell culture tests using MG-63 osteosarcoma human cells revealed improved biomineralization, cell viability, alkaline phosphatase (ALP) activity after 10 days of cell culture, the porous and interconnected nanofibers aided the growth and distribution of osteoblasts within the scaffolds [

2.1.7 Skeletal muscle tissue engineering

Skeletal muscle tissue engineering aims are to develop 3D substitutes for the treatment volumetric loss of muscle, alignment scaffolds produce signals that guide myotube, generating cell immersion and growing into the substrate [

| Polymer | Solvent | Electrospinning processing parameters | Fiber diameter | Porosity | Main outcomes | |||

| Voltage | Flow rate | Distance | Collector | |||||

| Fibrinogen 1 %, PEO 0,2 % | Deionized water | 4.5 kV | 7.5 mL/h | 8 cm | Fibrinogen solution bath | -- | -- | C2C12 proliferation and elongation [ |

| PCL 15 % (w/w) | DMF and acetone (1:1) | 10 kV | 1.08 mL/h | 10 cm | Aluminum foil | 468 nm | -- | Cell growth of fibroblast [ |

Guo et. al. 2019, generated 3D alignment scaffolds of fibrinogen 1 % /polyethylene oxide (PEO) 0.2 % dissolved in deionized water and collected in fibrinogen solution bath that contained Calcium chloride (CaCl2) and C2C12s myoblasts cells, these cells were immersed onto this scaffold, and exhibit myogenic differentiation and proliferation at 7 days of in vitro culture, conductivity, viscosity, surface tension and osmolarity of the solution help regulate the amount of electrical charge and mechanical shear to which the cells are subjected during the process [

Zhou et. al. 2019, created a 3D scaffold of PCL (Mw: 80.000 Da), 15 % (w/w) in dimethylformamide (DMF) and acetone (1:1) as solvent and collected aluminum foil, with aligned nanofibers and cultured with fibroblast per 7 days similar to skeletal muscle, the length-width and tilt angle of the double-bevel collector influenced the organization of the nanofibers within the 3D scaffold [

2.2 Industrial applications

Wet electrospinning for industrial applications has been used in water purification and air filter, biomedical sensors and flame retardants.

2.2.1 Water purification and air filters

Heavy metal ions in the water represent a health risk. Lead can be carcinogenic even at very low concentration, so it is desirable materials for the removal of heavy metal ions in water, with high ion adsorption. Nanofibers have the advantage of high surface area and the existence of abundant adsorption sites [

| Polymer | Solvent | Electrospinning processing parameters | Fiber diameter | Porosity | Main outcomes | |||

| Voltage | Flow rate | Distance | Collector | |||||

| PCL 10 wt % | (DCM)/ (EtOH) | 17 kV | 1.19 mL/h | 12 cm | GO in ethanol | 3-4 µm | PCL45/GO: 92 % PCL80/GO: 96 % | Sorption capacity to removal phenol from water [ |

| CA 17 wt % | DMAc and acetone | 19 kV | -- | 10 cm | NaCl aqueous solution | 450 nm | 2.2 μm | Superoleophobicit with an efficiency of 99 % [ |

| PA (10-25 % w/v) | Formic acid | 15,5 kV | 0,06 mL/h | 8cm | Ethanol | 35–117 nm | (97.8 ± 2.2) % | Extraction of chlorobenzenes in water by microextraction method [ |

| PLLA/PDLA-SC | DCM and DMF (8: 2 w / w) | 17 kV | 0,7 mL/h | 15 cm | Tertiary butanol | (349 ± 89) nm | 99.8 % | Efficiency filtration of HEPA to catch ultrafine particles [ |

Maio et. al. 2020, development 3D scaffolds of polycaprolactone (PCL) (Mw: 45.000 Da and 80.000 Da), 10 % wt in dichloromethane (DCM)/ Ethanol (EtOH) (3:1 by volume) and collected in graphene oxide (GO) (0,5 mg/L) in ethanol, for phenol removal for water treatment, as a reusable green device that has sorption capacity, the surface tension of the ethanol allowed the polycaprolactone nanofibers to sink thus allowing the formation of 3D scaffolds [

Hong et. al. 2018, created 3D scaffolds of cellulose acetate (CA) (Mw: 70.000 Da) 17 % wt, in dimethylacetamide (DMAc) and acetone volume ratio of (2: 1), and collected in 150 mL of 1 M NaCl aqueous solution. 3D scaffold removed oil from water and showed excellent underwater superoleophobicity with an efficiency of 99 %, the remaining oil content was very low (<29 ppm), the membrane had a high oil/water separation flux and high oil intrusion pressure [

Bagheri et. al. 2018, fabricated 3D scaffolds of polyamide (nylon-6) (PA) (10-25 % w/v) in formic acid as solvent, and collected in ethanol. PA scaffold exhibit better extraction efficiency 8–10 times greater of chlorobenzenes (CB) in water than 2D nanofibrous, the limits of detection are in the range from 0.8–3 pg/ml. Results, verifies their suitability as an extractive phase in the method, needle trap microextraction (NTME) [

Current air filter aims are to eliminate ultrafine particles with a size smaller than 0.1 μm, to create a healthier environment. By the use of polymers with low cost and high performance to capture these particles, nanofibrous filters exhibit higher filtration efficiency than microfibrous filters, due to larger specific surface area that increases diffusion and intercept capture. Currently, high-efficiency particulate arrestance (HEPA) filters have a removal efficiency of 99.97 % for particles with sizes to 0.3 μm, but their efficiency for removal of ultrafine particles is relatively low [69]. For air filter have been developed nanofibrous aerogels of Poly(L-lactide) PLLA/ Poly(D-lactide) PDLA, exhibit good compressive resistance and combined with a layer of HEPA filter improve the filtration efficiency for ultrafine particles (Table 8) [

Ma et. al. 2019, designed nanofibrous aerogels of PLLA (Mw: 9.12 × 10. g/mol) /PDLA (Mw: 3.98 × 10. g/mol) 10 % wt dissolved in dichloromethane and N-N dimethylformamide in a ratio (8:2 w/w), and collected in Tertiary butanol. This scaffold exhibits good compressive resistance and combined with a layer of HEPA filter improve the filtration efficiency for ultrafine particles, attributed to the high porosity, as well as the slip flow effect of nanofibers [

2.2.2 Energy

Nanofibers in the energetic applications have been used due to their properties of large surface area to volume ratio that allow increased the energetic efficiency, high conductivity, flexibility and performance. The most important energy-related uses are as follows: Solar cells, Li-Batteries, Super-Capacitors, Fuel Cells, Nanogenerators, Hydrogen storage [

Although, multiple investigations with energetic applications have been carried out in electrospinning, the applications of 3D nanofibers produced in wet electrospinning have been little explored. Lithium ion batteries (LiB) store energy and have been commonly applied in mobile phones and laptops, due to their high energy density and long-life cycle [

Rechargeable lithium-O. batteries have attracted more attention than lithium-ion batteries, due to their higher energy density (11.680 Wh/kg), they are more compact and lighter. Some problems with these types of batteries are limited discharge capacity and poor charge / discharge cycle stability due to a low pore volume utilization rate. Wet electrospinning allows the creation of a 3D network for manufacturing oxygen electrode materials, highly porous, with electrical conductivity and electrochemical activity, providing an interconnected oxygen diffusion pathway within the membrane, facilitating the oxygen reduction reaction (ORR) and the oxygen evolution reaction (OER) [

Lim et.al. 2019, prepared a nitrogen-doped hollow carbon fiber using polydopamine and electrospun polystyrene (PS) (Mw: 350.000 Da) 30 wt % in N,N-dimethylformamide (DMF), collected in ethanol as coagulant, and nitrogen-doped 3D scaffolds as sacrificial template, for the oxygen electrode of Li-O. batteries. Due to the synergistic effects of nitrogen doping and hollow fibrous structure, the discharge capacity and recharge significantly improved, with an overpotential of ORR / OER reduced [

| Polymer | Solvent | Electrospinning processing parameters | Fiber diameter | Porosity | Main outcomes | |||

| Voltage | Flow rate | Distance | Collector | |||||

| PS 30 wt % | DMF | 20 kV | -- | 20 cm | Ethanol | 2.7 μm | -- | Highly effective oxygen electrode for Li-O2 batteries [ |

| PAN 5 wt % | Dimethylformamide (DMF) | 20 kV | 2 mL/h | 10 cm | GO coagulation bath | -- | -- | Capacitance of 221 F/g at 10 mV/s [ |

Supercapacitors (SC) or electrochemical capacitors are energy storage devices, applied in electricity and electronics. Due to its high-power output, long life cycle, fast charge and discharge times, and low maintenance cost. Depending on different energy storage mechanisms, SCs can be classified into pseudo-capacitors (PC) and electric double-layer capacitors (EDLC). PCs store energy based on rapidly reversible surface redox reactions (chemical adsorption / desorption), while EDLCs store energy by adsorption and desorption of ions at the electrode and electrolyte interface. Wet electrospinning allows the manufacture of flexible double-layer electrical capacitors (EDLC) based on highly porous nanofibers of polymers such as Polybenzimidazole (PBI) or polyaniline (PANI) with carbon or graphene nanofibers and metal oxides such as RuO2, MnO2 [

Shi et. al. 2020, developed polyacrylonitrile (PAN) (Mw: 150.000 Da) 5 % wt, in dimethylformamide (DMF), and collected in a reduced graphene oxide (rGO) and ethanol. Double layer intercalated flexible supercapacitor (EDLC) electrode, for energy storage manufactured by a layer-by-layer wet electrospinning process with a dilute graphene oxide (GO) solution as coagulation liquid and subsequent thermal reduction treatment at 300ªC.

The rGO / PAN nanofibers demonstrated exceptional double-layer capacitance of 221 F / g at 10 mV / s, controllable electrical conductivity of 125 S / m, and stable cycling performance that retains a slight increase in capacitance after 10.000 cycles, NH. gas released from the cyclization of PAN fibers induced N-doping on the rGO surfaces, further enhancing the charge storage capacity [

2.2.3 Biomedical sensors and flame retardant

Nanofibers with additives such as graphene oxide and carbon nanotubes (MWCNT), increases the electrical conductivity. Some polymers are also conductors between them polyacrylinitrile (PAN) and poly (3,4-ethylene dioxythiophene) poly (styrene sulfonate) (PEDOT: PSS), for applications as wearable strain sensors and conductive textiles. Silica nanoparticles (SNP) increase the flame retardant (Table 10) [

| Polymer | Solvent | Electrospinning processing parameters | Fiber diameter | Porosity | Main outcomes | |||

| Voltage | Flow rate | Distance | Collector | |||||

| TPU 10 wt % | DMF 98 % | 30 kV | 1.2 mL/h | 12 cm | PEDOT: PSS) 1.3 wt % in water | 340 nm | -- | Exhibited a stabilized ohmic behavior [ |

| TPU 10 % wt | DMF 98 % | 30 kV | 1 mL/h | 10 cm | PEDOT: PSS 1.3 % wt in water | 170nm | -- | Under different percentages of tensile strain demonstrate an ohmic behavior [ |

| CNF | Water | -- | 50 μL/min | -- | HCl and SNP | CNF: 12.4 ± 1.0 μm CNF/10SNP: (13.3 ± 1.4) μm CNF/20SNP: (15.1 ± 1.4) μm | -- | Flame retardant [ |

Shaker et. al. 2019, fabricated a sensible and conductive sensor of thermoplastic polyurethane (TPU) (Mw: 107.020 g/mol) at 10 wt % in dimethylformamide (DMF) and collected in poly (3,4-ethylene dioxythiophene) poly (styrene sulfonate) (PEDOT: PSS) 1.3 % wt in water and silicon rubber (SR) substrate, for sense rapid and minute deformation actions. The TPU/PEDOT: PSS strain gauge sensor manufactured presented a stabilized kΩ scale electrical resistance, regardless of the applied voltage and temperature value, demonstrated its durability and repeatability of use up to 15 cycles and its sensitivity to detect small loads [

Shaker et. al. 2017, fabricated nanofibers sensor of thermoplastic polyurethane (TPU) (107.020 g/mol) 10 % wt, in dimethylformamide (DMF) and collected in co-polymer poly (3,4-ethylenedioxythiophene)/ poly (styrenesulfonate) (PEDOT: PSS) 1.3 % wt in water and Kapton substrate, suitable for high temperature (90 ºC) strain sensing applications, the fabricated TPU/PEDOT: PSS scaffold showed a great improvement in electrical conductivity on the KΩ scale [

Nechyporchuk et. al. 2017, produced fibers from wood-derived cellulose nanofibers (CNF) (0.75 % wt) in deionized water and collected in 250 mL of aqueous solution of hydrochloric acid (HCl) at pH 2, and silica nanoparticles (SNP) at 44 % wt. The flame retardant until 600°C was attributed to silica nanoparticles that promote carbon formation and thermal insulation of the fiber surface was demonstrated, the incorporation of SNP on the surface of the nanofibers slightly reduced the toughness, however, preserved the Young's modulus [

3. PERSPECTIVES AND FUTURE TRENDS

Wet electrospinning is a technique that allows the development of 3D scaffolds with a high surface-to-volume ratio and an internal network of macropores, which improve cell infiltration for tissue engineering. Compared to traditional electrospinning, where packing density makes its pores nanometer-sized and hinders cell infiltration.

Wet electrospinning has several application areas, such as tissue engineering and industry. The parameters of the wet electrospinning solution and equipment influence the average diameter and morphology of fibers. For example, it is necessary to determine the right concentration of the solution to avoid fiber fusion and to maintain an adequate pore size to allow the formation of continuous nanofibers.

Environmental parameters (temperature and relative humidity) influence the reduction of nanofiber diameter and the increase of porosity, respectively. The equipment parameters (voltage, flow rate and distance between the needle tip) have influence on the morphology either in the form of ribbon or coil-fiber, the deposition time is associated with the thickness of the 3D scaffold, while, for the selection of the non-coagulant solvent used as collector influences the surface tension if it is very high (water: 72. 86 mN/m) the fibers float and if the surface tension is low (ethanol: 22.10 mN/M, chloroform: 26.67 mN/m, methanol: 22.50 mN/m, dimethylformamide: 36.40 mN/m) the fibers submerge, become more porous, less compact and with higher mechanical properties. The mixture of solvents in the ethanol/water coagulation bath with a surface tension lower than 28.52 mN/m allows continuous fibers to form, most works report a ratio (9:1) respectively. The use of surfactants reduces the surface tension of water, which improves fiber formation.

Long exposure to chemicals during the manufacturing process can be detrimental to cells; as a future prospect, tissue engineers should look to the use of non-toxic solvents in the coagulation bath.

Wet electrospinning allows the creation of microfibers, or nanofibers, from composite materials by combining natural and synthetic polymers. These scaffolds are chemically functionalized in situ in the coagulation bath to modify the surface of the fibers with additives such as nanoparticles, hydrogels, bioactive agents, proteins, drugs and growth factors, which increase mechanical properties (Young's modulus and compression) and improve cell attachment sites for tissue engineering and enhance properties for industrial applications.

Some research functionalizes 3D scaffolds with hydrogels to create an extracellular matrix (ECM)-like microenvironment, which has improved cell viability and proliferation.

It has been established that the required porosity percentage for tissue engineered scaffolds is greater than 80 %, which is significant for cell infiltration and necessary for homogeneous tissue regeneration. To date, in vitro studies with cells and some in vivo studies in animals have been performed. In vivo studies in humans using 3D scaffolds that respond to the specific needs of each patient are needed. Future work could explore the regeneration of other tissues, in which mesenchymal stem cell differentiation is stimulated along with bioactive agents.

Composite scaffolds improve their properties, more research is expected in the use of natural and synthetic additives (hydrophilic and hydrophobic) to provide better solutions to current treatments.

Research on conductive materials could lead to the development of new sensors, and research on carbon-based materials such as nanotubes and graphene oxide could contribute to the development of flame-retardant materials.

Wet electrospinning is expected to increase its industrial production of nonwoven fibers, for which the multi-needle technique has been used to increase productivity on a larger scale.

So far, wet electrospinning has demonstrated its applicability in interdisciplinary areas such as water purification and air filters, biomedical sensors and flame-retardant fibers, but other potential industrial uses need to be explored in future work.

4. CONCLUSIONS

Wet electrospinning is a technique of nanofibers scaffold fabrication that allows 3D structure, high porosity and high surface area. By a simple change in the metal collector of traditional electrospinning to a coagulation bath, many parameters have influenced in the fiber formation such as concentration of the solution, wet electrospinning configuration apparatus and the surface tension of the solvent. The fibers have micro porosity that improved cell infiltration, and with the addition of carbon nanotubes or graphene oxide increased the mechanical properties of the scaffold. Wet electrospinning can be development by coaxial technique to produce fibers with desired properties and structure core-shell and by multineedle technique to improve their production. Wet electrospinning has applications in tissue engineering and industrial applications. In the future is expected that other possible applications be explored thanks to the possibility of creating less packed and more porous fibers, which can be chemically functionalized in situ to obtain improved characteristics. The challenging aspects of wet electrospinning for future work are aimed at finding non-solvent solutions that are less toxic, but do not lose their effect on the formation of 3D nanofibers and specific design according to their application. In addition, a greater study of the physical and chemical properties of the polymers used in wet electrospinning is necessary in order to adapt their performance in terms of costs, biocompatibility and similarity with ECM for tissue engineering applications and improve the mechanical resistance for industrial applications.

One of the aspects to work on in the future involves 3D scaffolds morphology, and how these in the company of growth factors and bioactive agents influences the differentiation of stem cells. Finally, future work should evaluate the in vivo efficacy of 3D scaffolds for the regeneration of specific tissues, so far, few studies have evaluated its application in mice, but its use in humans could be extended with more in-depth studies.

5. ACKNOWLEDGMENTS

The authors thanks to Metropolitan Technological Institute (ITM) for supporting the development of the high-impact project P20209 "Nanostructured polymer plus fibroin and silver nanoparticles nanostructured membranes of polymer plus fibroin and silver nanoparticles built by electrospinning techniques stimulated with electrical signals and evaluated on bone cells".

CONFLICTS OF INTEREST

The authors declare that there is no conflict of interest.

AUTHOR CONTRIBUTIONS

Maria Elena Moncada-Acevedo: Co-directed the research project. She worked actively (leading) the writing in the different sections of the review article, and she worked in the analysis of the results, discussion, and conclusions; Yarledis Hurtado-Henao: She was young researcher in the project. She wrote some sections of the review article; Mónica Liliana Mejía Suaza: Co-directed the research project and chose the methods implemented. She determined the methodology. She revised the manuscript, corrected the writing style, and improved the article in the different sections.

6. REFERENCES

- arrow_upward [1] D. I. Braghirolli; D. Steffens; P. Pranke, “Electrospinning for regenerative medicine: a review of the main topics”, Drug Discov. Today, vol. 19, no. 6, pp. 743–753, Jun. 2014. https://doi.org/10.1016/j.drudis.2014.03.024

- arrow_upward [2] N. Okutan; P. Terzi; F. Altay, “Affecting parameters on electrospinning process and characterization of electrospun gelatin nanofibers”, Food Hydrocoll., vol. 39, pp. 19–26, Aug. 2014. https://doi.org/10.1016/j.foodhyd.2013.12.022

- arrow_upward [3] A. Barhoum; K. Pal; H. Rahier; H. Uludag; I. S. Kim; M. Bechelany, “Nanofibers as new-generation materials: From spinning and nano-spinning fabrication techniques to emerging applications”, Appl. Mater. Today, vol. 17, pp. 1–35, Dec. 2019. https://doi.org/10.1016/j.apmt.2019.06.015

- arrow_upward [4] W. Lin; M. Chen; T. Qu; J. Li; Y. Man, “Three‐dimensional electrospun nanofibrous scaffolds for bone tissue engineering”, J. Biomed. Mater. Res. Part B Appl. Biomater., vol. 108, no. 4, pp. 1311–1321, May 2020. https://doi.org/10.1002/jbm.b.34479

- arrow_upward [5] M. Rahmati et al., “Electrospinning for tissue engineering applications”, Prog. Mater. Sci., vol. 117, p. 100721, Apr. 2021. https://doi.org/10.1016/j.pmatsci.2020.100721

- arrow_upward [6] A. Khamhaengpol; S. Siri, “Composite Electrospun Scaffold Derived from Recombinant Fibroin of Weaver Ant (Oecophylla smaragdina) as Cell-Substratum”, Appl. Biochem. Biotechnol., vol. 183, no. 1, pp. 110–125, Sep. 2017. https://doi.org/10.1007/s12010-017-2433-4

- arrow_upward [7] M. M. Sayed et al., “Enhancing mechanical and biodegradation properties of polyvinyl alcohol/silk fibroin nanofibers composite patches for Cardiac Tissue Engineering”, Mater. Lett., vol. 255, p. 126510, Nov. 2019. https://doi.org/10.1016/j.matlet.2019.126510

- arrow_upward [8] N. Rahimi Tanha; M. Nouri, “An experimental study on the coaxial electrospinning of silk fibroin/poly(vinyl alcohol)–salicylic acid core-shell nanofibers and process optimization using response surface methodology”, Journal of Industrial Textiles, vol. 48, no. 5, pp. 884–903, Nov. 2018. https://journals.sagepub.com/doi/10.1177/1528083717747334

- arrow_upward [9] R. Giovanni; U. A. Wibowo; H. Judawisastra; A. Barlian, “Growth of Human Dermal Fibroblasts on Polyvinyl Alcohol-Silk Fibroin Nanofiber Scaffold”, J. Math. Fundam. Sci., vol. 51, no. 3, pp. 294–308, Dec. 2019. https://doi.org/10.5614/j.math.fund.sci.2019.51.3.7

- arrow_upward [10] C. M. Srivastava; R. Purwar; A. P. Gupta, “Enhanced potential of biomimetic, silver nanoparticles functionalized Antheraea mylitta (tasar) silk fibroin nanofibrous mats for skin tissue engineering”, Int. J. Biol. Macromol., vol. 130, pp. 437–453, Jun. 2019. https://doi.org/10.1016/j.ijbiomac.2018.12.255

- arrow_upward [11] M. Joshi; A. Bhattacharyya, “Nanotechnology – a new route to high-performance functional textiles”, Text. Prog., vol. 43, no. 3, pp. 155–233, Sep. 2011. https://doi.org/10.1080/00405167.2011.570027

- arrow_upward [12] B. Sun et al., “Advances in three-dimensional nanofibrous macrostructures via electrospinning”, Prog. Polym. Sci., vol. 39, no. 5, pp. 862–890, May 2014. https://doi.org/10.1016/j.progpolymsci.2013.06.002

- arrow_upward [13] M. L. Mejía Suaza; M. E. Moncada; C. P. Ossa-Orozco, “Characterization of Electrospun Silk Fibroin Scaffolds for Bone Tissue Engineering: A Review”, TecnoLógicas, vol. 23, no. 49, pp. 33–51, Sep. 2020. https://doi.org/10.22430/22565337.1573

- arrow_upward [14] A. K. Figen, “History, Basics, and Parameters of Electrospinning Technique”, Electrospun Materials and Their Allied Applications, pp. 53–69, 2020. https://doi.org/10.1002/9781119655039.ch2

- arrow_upward [15] J. Xue; T. Wu; Y. Dai; Y. Xia, “Electrospinning and Electrospun Nanofibers: Methods, Materials, and Applications”, Chem. Rev., vol. 119, no. 8, pp. 5298–5415, Apr. 2019. https://doi.org/10.1021/acs.chemrev.8b00593

- arrow_upward [16] N. Bhardwaj; S. C. Kundu, “Electrospinning: A fascinating fiber fabrication technique”, Biotechnol. Adv., vol. 28, no. 3, pp. 325–347, May-Jun. 2010. https://doi.org/10.1016/j.biotechadv.2010.01.004

- arrow_upward [17] X. Wang; T. Lin, Needleless Electrospinning of Nanofibers. Jenny Stanford Publishing, 2013. https://doi.org/10.1201/b15489

- arrow_upward [18] J. He; Y. Zhou, “Multineedle Electrospinning” in Electrospinning: Nanofabrication and Applications, Elsevier, 2019, pp. 201–218. https://doi.org/10.1016/B978-0-323-51270-1.00006-6

- arrow_upward [19] G. Kabay; C. Demirci; G. Kaleli Can; A. E. Meydan; B. G. Daşan; M. Mutlu, “A comparative study of single-needle and coaxial electrospun amyloid-like protein nanofibers to investigate hydrophilic drug release behavior”, Int. J. Biol. Macromol., vol. 114, pp. 989–997, Jul. 2018. https://doi.org/10.1016/j.ijbiomac.2018.03.182

- arrow_upward [20] Y. E. Kiyak; E. Cakmak, “Nanofiber Production Methods”, Electronic Journal of Vehicle Technologies/Tasit Teknolojileri Elektronik Dergisi, vol. 8, no. 3, pp. 49–60, 2014. https://docplayer.net/35000934-Nanofiber-production-methods-nanolif-uretim-yontemleri.html

- arrow_upward [21] D. M. dos Santos; D. S. Correa; E. S. Medeiros; J. E. Oliveira; L. H. C. Mattoso, “Advances in Functional Polymer Nanofibers: From Spinning Fabrication Techniques to Recent Biomedical Applications”, ACS Appl. Mater. Interfaces, vol. 12, no. 41, pp. 45673–45701, Sep. 2020. https://doi.org/10.1021/acsami.0c12410

- arrow_upward [22] M. B. Taskin; L. H. Klausen; M. Dong; M. Chen, “Emerging wet electrohydrodynamic approaches for versatile bioactive 3D interfaces”, Nano Res., vol. 13, no. 2, pp. 315–327, Feb. 2020. https://doi.org/10.1007/s12274-020-2635-x

- arrow_upward [23] D. Puppi; F. Chiellini, “ “Wet-spinning of biomedical polymers: from single-fibre production to additive manufacturing of three-dimensional scaffolds”, Polym. Int., vol. 66, no. 12, pp. 1690–1696, Dec. 2017. https://doi.org/10.1002/pi.5332

- arrow_upward [24] H. El-sayed; C. Vineis; A. Varesano; S. Mowafi; R. A. Carletto; C. Tonetti; M. Abou Taleb, “A critique on multi-jet electrospinning : State of the art and future outlook”, Nanotechnology Reviews, vol. 8, no. 1, pp. 236–245, 2019.

- arrow_upward [25] IGTPAN, “Technologies employed in the manufacture of acrylic fibers”, 2016. http://www.igtpan.com/Ingles/tecnologia-fibra.asp

- arrow_upward [26] A. Maio; M. Gammino; E. F. Gulino; B. Megna; P. Fara; R. Scaffaro, “Rapid One-Step Fabrication of Graphene Oxide-Decorated Polycaprolactone Three-Dimensional Templates for Water Treatment”, ACS Appl. Polym. Mater., vol. 2, no. 11, pp. 4993–5005, Sep. 2020. https://doi.org/10.1021/acsapm.0c00852

- arrow_upward [27] F. Naghizadeh; A. Solouk; S. B. Khoulenjani, “Osteochondral scaffolds based on electrospinning method: General review on new and emerging approaches”, Int. J. Polym. Mater. Polym. Biomater., vol. 67, no. 15, pp. 913–924, Oct. 2018.https://doi.org/10.1080/00914037.2017.1393682

- arrow_upward [28] F. Mokhtari; M. Salehi; F. Zamani; F. Hajiani; F. Zeighami; M. Latifi, “Advances in electrospinning: The production and application of nanofibres and nanofibrous structures”, Text. Prog., vol. 48, no. 3, pp. 119–219, Jul. 2016. https://doi.org/10.1080/00405167.2016.1201934

- arrow_upward [29] W. Yang; H. Yu; M. Zhu; H. Bai; Y. Chen, “Poly(m‐Phenylene Isophthalamide) Ultrafine Fibers from an Ionic Liquid Solution by Dry‐Jet‐Wet‐Electrospinning”, J. Macromol. Sci. Part B, vol. 45, no. 4, pp. 573–579, Aug. 2006. https://doi.org/10.1080/00222340600770129

- arrow_upward [30] C. Kim; S. Joshi; G. Cauwenberghs, “Patent Application Publication: US 2019 / 0253069 A1”, vol. 1, pp. 1–10, 2019. https://patents.google.com/patent/US20190046689A1/en?oq=11%2f825%2c540

- arrow_upward [31] M. Rafiei; E. Jooybar; M. J. Abdekhodaie; M. Alvi, “Construction of 3D fibrous PCL scaffolds by coaxial electrospinning for protein delivery”, Mater. Sci. Eng. C, vol. 113, p. 110913, Aug. 2020. https://doi.org/10.1016/j.msec.2020.110913

- arrow_upward [32] Y. Zhou; Z. Hu; D. Du; G. Z. Tan, “The effects of collector geometry on the internal structure of the 3D nanofiber scaffold fabricated by divergent electrospinning”, Int. J. Adv. Manuf. Technol., vol. 100, no. 9–12, pp. 3045–3054, Feb. 2019. https://doi.org/10.1007/s00170-018-2899-4

- arrow_upward [33] A. Sonseca et al., “Architectured helically coiled scaffolds from elastomeric poly(butylene succinate) (PBS) copolyester via wet electrospinning”, Mater. Sci. Eng. C, vol. 108, p. 110505, Mar. 2020. https://doi.org/10.1016/j.msec.2019.110505

- arrow_upward [34] S. S. Majidi; P. Slemming-Adamsen; M. Hanif; Z. Zhang; Z. Wang; M. Chen, “Wet electrospun alginate/gelatin hydrogel nanofibers for 3D cell culture”, Int. J. Biol. Macromol., vol. 118, pp. 1648–1654, Oct. 2018. https://doi.org/10.1016/j.ijbiomac.2018.07.005

- arrow_upward [35] M. K. Krishnamoorthi et al., “Robust Fabrication of Composite 3D Scaffolds with Tissue-Specific Bioactivity: A Proof-of-Concept Study”, ACS Appl. Bio Mate., vol. 3, no. 8, pp. 4974–4986, Aug. 2020. https://doi.org/10.1021/acsabm.0c00310

- arrow_upward [36] Y. Liu; A. Nguyen; A. Allen; J. Zoldan; Y. Huang; J. Y. Chen, “Regenerated cellulose micro-nano fiber matrices for transdermal drug release”, Mater. Sci. Eng. C, vol. 74, pp. 485–492, May 2017. https://doi.org/10.1016/j.msec.2016.12.048

- arrow_upward [37] O. C. Gunes; A. Z. Albayrak; S. Tasdemir; A. Sendemir, “Wet-electrospun PHBV nanofiber reinforced carboxymethyl chitosan-silk hydrogel composite scaffolds for articular cartilage repair”, J. Biomater. Appl., vol. 35, no. 4–5, pp. 515–531, Oct. 2020. https://doi.org/10.1177/0885328220930714

- arrow_upward [38] Y. Li et al., “Cell-free 3D wet-electrospun PCL/silk fibroin/Sr2+ scaffold promotes successful total meniscus regeneration in a rabbit model”, Acta Biomater., vol. 113, pp. 196–209, Sep. 2020. https://doi.org/10.1016/j.actbio.2020.06.017

- arrow_upward [39] A. F. Girão; Â. Semitela; G. Ramalho; A. Completo; P. A. A. P. Marques, “ “Mimicking nature: Fabrication of 3D anisotropic electrospun polycaprolactone scaffolds for cartilage tissue engineering applications”, Compos. Part B Eng., vol. 154, pp. 99–107, Dec. 2018. https://doi.org/10.1016/j.compositesb.2018.08.001

- arrow_upward [40] P. Das; M. D. DiVito; J. A. Wertheim; L. P. Tan, “Collagen-I and fibronectin modified three-dimensional electrospun PLGA scaffolds for long-term in vitro maintenance of functional hepatocytes”, Mater. Sci. Eng. C, vol. 111, p. 110723, Jun. 2020. https://doi.org/10.1016/j.msec.2020.110723

- arrow_upward [41] J. H. Brown; P. Das; M. D. DiVito; D. Ivancic; L. P. Tan; J. A. Wertheim, “Nanofibrous PLGA electrospun scaffolds modified with type I collagen influence hepatocyte function and support viability in vitro”, Acta Biomater., vol. 73, pp. 217–227, Jun. 2018. https://doi.org/10.1016/j.actbio.2018.02.009

- arrow_upward [42] M. Naseri-Nosar; S. Farzamfar; M. Salehi; A. Vaez; R. Tajerian; M. Azami, “Erythropoietin/aloe vera-releasing wet-electrospun polyvinyl alcohol/chitosan sponge-like wound dressing: In vitro and in vivo studies”, J. Bioact. Compat. Polym., vol. 33, no. 3, pp. 269–281, May 2018. https://doi.org/10.1177/0883911517731793

- arrow_upward [43] M. N. Nosar; M. Salehi; S. Ghorbani; S. P. Beiranvand; A. Goodarzi; M. Azami, “Characterization of wet-electrospun cellulose acetate based 3-dimensional scaffolds for skin tissue engineering applications: influence of cellulose acetate concentration”, Cellulose, vol. 23, no. 5, pp. 3239–3248, Oct. 2016. https://doi.org/10.1007/s10570-016-1026-7

- arrow_upward [44] X. Jing; H. Li; H.-Y. Mi; Y.-J. Liu; Y.-M. Tan, “Fabrication of fluffy shish-kebab structured nanofibers by electrospinning, CO2 escaping foaming and controlled crystallization for biomimetic tissue engineering scaffolds”, Chem. Eng. J., vol. 372, pp. 785–795, Sep. 2019. https://doi.org/10.1016/j.cej.2019.04.194

- arrow_upward [45] S. Ghorbani et al., “Combined effects of 3D bone marrow stem cell-seeded wet-electrospun poly lactic acid scaffolds on full-thickness skin wound healing”, Int. J. Polym. Mater. Polym. Biomater., vol. 67, no. 15, pp. 905–912, Oct. 2018.https://doi.org/10.1080/00914037.2017.1393681

- arrow_upward [46] M. Zhang; H. Lin; Y. Wang; G. Yang; H. Zhao; D. Sun, “Fabrication and durable antibacterial properties of 3D porous wet electrospun RCSC/PCL nanofibrous scaffold with silver nanoparticles”, Appl. Surf. Sci., vol. 414, pp. 52–62, Aug. 2017. https://doi.org/10.1016/j.apsusc.2017.04.052

- arrow_upward [47] C. Jiang; K. Wang; Y. Liu, C. Zhang; B. Wang, “Textile-based sandwich scaffold using wet electrospun yarns for skin tissue engineering”, J. Mech. Behav. Biomed. Mater., vol. 119, p. 104499, Jul. 2021. https://doi.org/10.1016/j.jmbbm.2021.104499

- arrow_upward [48] D. D. Akolpoğlu Başaran; U. Gündüz; A. Tezcaner; D. Keskin, “Topical delivery of heparin from PLGA nanoparticles entrapped in nanofibers of sericin/gelatin scaffolds for wound healing”, Int. J. Pharm., vol. 597, p. 120207, Mar. 2021. https://doi.org/10.1016/j.ijpharm.2021.120207

- arrow_upward [49] L. Wang; Y. Wu; T. Hu; P. X. Ma; B. Guo, “Aligned conductive core-shell biomimetic scaffolds based on nanofiber yarns/hydrogel for enhanced 3D neurite outgrowth alignment and elongation”, Acta Biomater., vol. 96, pp. 175–187, Sep. 2019. https://doi.org/10.1016/j.actbio.2019.06.035

- arrow_upward [50] S. Ghorbani; T. Tiraihi; M. Soleimani, “Differentiation of mesenchymal stem cells into neuron-like cells using composite 3D scaffold combined with valproic acid induction”, J. Biomater. Appl., vol. 32, no. 6, pp. 702–715, Jan. 2018. https://doi.org/10.1177/0885328217741903

- arrow_upward [51] S. Farzamfar et al., “Neural tissue regeneration by a gabapentin-loaded cellulose acetate/gelatin wet-electrospun scaffold”, Cellulose, vol. 25, no. 2, pp. 1229–1238, Feb. 2018. https://doi.org/10.1007/s10570-017-1632-z

- arrow_upward [52] F. Zamani; M. Amani-Tehran; A. Zaminy; M.-A. Shokrgozar, “Conductive 3D structure nanofibrous scaffolds for spinal cord regeneration”, Fibers Polym., vol. 18, no. 10, pp. 1874–1881, Oct. 2017. https://doi.org/10.1007/s12221-017-7349-7

- arrow_upward [53] F. F. F. Garrudo et al., “The effect of electrospun scaffolds on the glycosaminoglycan profile of differentiating neural stem cells”, Biochimie, vol. 182, pp. 61–72, Mar. 2021. https://doi.org/10.1016/j.biochi.2021.01.001

- arrow_upward [54] M. Naseri-Nosar; M. Salehi; S. Hojjati-Emami, “Cellulose acetate/poly lactic acid coaxial wet-electrospun scaffold containing citalopram-loaded gelatin nanocarriers for neural tissue engineering applications”, Int. J. Biol. Macromol., vol. 103, pp. 701–708, Oct. 2017. https://doi.org/10.1016/j.ijbiomac.2017.05.054

- arrow_upward [55] V. D. Ranjan et al., “A microfiber scaffold-based 3D in vitro human neuronal culture model of Alzheimer’s disease”, Biomater. Sci., vol. 8, no. 17, pp. 4861–4874, 2020. https://doi.org/10.1039/d0bm00833h

- arrow_upward [56] H. Alissa Alam; A. D. Dalgic; A. Tezcaner; C. Ozen; D. Keskin, “A comparative study of monoaxial and coaxial PCL/gelatin/Poloxamer 188 scaffolds for bone tissue engineering”, Int. J. Polym. Mater. Polym. Biomater., vol. 69, no. 6, pp. 339–350, Apr. 2020. https://doi.org/10.1080/00914037.2019.1581198

- arrow_upward [57] A. Kara; O. C. Gunes; A. Z. Albayrak; G. Bilici; G. Erbil; H. Havitcioglu, “Fish scale/poly(3-hydroxybutyrate- co -3-hydroxyvalerate) nanofibrous composite scaffolds for bone regeneration”, J. Biomater. Appl., vol. 34, no. 9, pp. 1201–1215, Apr. 2020. https://doi.org/10.1177/0885328220901987

- arrow_upward [58] O. Colpankan Gunes et al., “Three-dimensional silk impregnated HAp/PHBV nanofibrous scaffolds for bone regeneration”, Int. J. Polym. Mater. Polym. Biomater., vol. 68, no. 5, pp. 217–228, Mar. 2019. https://doi.org/10.1080/00914037.2018.1443928

- arrow_upward [59] Y. E. Choe; G. H. Kim, “A PCL/cellulose coil-shaped scaffold via a modified electrohydrodynamic jetting process”, Virtual Phys. Prototyp., vol. 15, no. 4, pp. 403–416, Oct. 2020. https://doi.org/10.1080/17452759.2020.1808269

- arrow_upward [60] A. D. Dalgic; D. Atila; A. Karatas; A. Tezcaner; D. Keskin, “Diatom shell incorporated PHBV/PCL-pullulan co-electrospun scaffold for bone tissue engineering”, Mater. Sci. Eng. C, vol. 100, pp. 735–746, Jul. 2019. https://doi.org/10.1016/j.msec.2019.03.046

- arrow_upward [61] M. Kim; Y. Choe; G. Kim, “Injectable hierarchical micro/nanofibrous collagen-based scaffolds”, Chem. Eng. J., vol. 365, pp. 220–230, Jun. 2019. https://doi.org/10.1016/j.cej.2019.02.044

- arrow_upward [62] E. Çatıker; E. Konuk; T. Gültan; M. Gümüşderelioğlu, “Enhancement of scaffolding properties for poly(3-hydroxybutyrate): blending with poly-β-alanine and wet electrospinning”, Int. J. Polym. Mater. Polym. Biomater., vol. 68, no. 6, pp. 338–349, Apr. 2019. https://doi.org/10.1080/00914037.2018.1552862

- arrow_upward [63] Y. Guo; J. Gilbert-Honick; S. M. Somers; H.-Q. Mao; W. L. Grayson, “Modified cell-electrospinning for 3D myogenesis of C2C12s in aligned fibrin microfiber bundles”, Biochem. Biophys. Res. Commun., vol. 516, no. 2, pp. 558–564, Aug. 2019. https://doi.org/10.1016/j.bbrc.2019.06.082

- arrow_upward [64] L. Wang; Y. Wu; B. Guo; P. X. Ma, “Nanofiber Yarn/Hydrogel Core–Shell Scaffolds Mimicking Native Skeletal Muscle Tissue for Guiding 3D Myoblast Alignment, Elongation, and Differentiation”, ACS Nano, vol. 9, no. 9, pp. 9167–9179, Sep. 2015. https://doi.org/10.1021/acsnano.5b03644

- arrow_upward [65] T. Uchibori; K. Takanari; R. Hashizume; N. J. Amoroso; Y. Kamei; W. R. Wagner, “Use of a pedicled omental flap to reduce inflammation and vascularize an abdominal wall patch”, J. Surg. Res., vol. 212, pp. 77–85, May 2017. https://doi.org/10.1016/j.jss.2016.11.052

- arrow_upward [66] R. Hashizume et al., “Morphological and mechanical characteristics of the reconstructed rat abdominal wall following use of a wet electrospun biodegradable polyurethane elastomer scaffold”, Biomaterials, vol. 31, no. 12, pp. 3253–3265, Apr. 2010. https://doi.org/10.1016/j.biomaterials.2010.01.051

- arrow_upward [67] H. Bagheri; F. Manshaei; O. Rezvani, “Three-dimensional nanofiber scaffolds are superior to two-dimensional mats in micro-oriented extraction of chlorobenzenes”, Microchim. Acta, vol. 185, no. 7, p. 322, Jul. 2018. https://doi.org/10.1007/s00604-018-2858-7

- arrow_upward [68] S. K. Hong; S. Bae; H. Jeon; M. Kim; S. J. Cho; G. Lim, “An underwater superoleophobic nanofibrous cellulosic membrane for oil/water separation with high separation flux and high chemical stability”, Nanoscale, vol. 10, no. 6, pp. 3037–3045, 2018. https://doi.org/10.1039/c7nr08199e