Energy Management Systems in Latin American Industry: Case Study Colombia

Sistemas de gestión de la energía en la industria latinoamericana: caso de estudio Colombia

Received: April 01, 2022

Accepted: July 01, 2022

Available: August 23, 2022

J. D. Beltrán-Gallego; M. Quintero-Ríos; D. López-García; S. X. Carvajal-Quintero, “Energy Management Systems in Latin American Industry: Case Study Colombia,” TecnoLógicas, vol. 25, nro. 54, e2379, 2022. https://doi.org/10.22430/22565337.2379

Abstract

The increase in energy demand, mainly due to the dependence of industry and transport on fossil fuels, has led to the extensive use of these fuels and an increase in greenhouse gas emissions, generating a severe environmental concern in all countries. Then, the need for a proportionate consumption of energy resources and the decarbonization of the economy to leverage the reduction of emissions into the atmosphere becomes evident. Therefore, implementing Energy Management Systems (EnMS) within industries makes sense, seeking to promote energy's rational and efficient use. Consequently, this paper presents a bibliographic review on the integration of EnMS in the industry, highlighting the main barriers and motivators for its implementation, emphasizing the leading role that management has within companies in converting these programs into sustainable initiatives in an extended time horizon. In addition, an analysis of the Latin American panorama is presented, especially the Colombian one, on the integration of mechanisms to improve energy efficiency in industries. One of the main conclusions evidenced was the need to increase support at the regulatory level for energy efficiency programs in the industry. Currently, greater prominence is given to renewable energy sources, which are a fundamental step for the energy transition but must be complemented with the rational and efficient use of resources. Here, the industry has an essential role in representing the segment of users that more energy traditionally consumes.

Keywords: Energy saving, industrial demand, energy efficiency, energy management systems, energy transition.

Resumen

El aumento de la demanda energética, debido principalmente a la dependencia de la industria y del transporte de los combustibles fósiles, ha llevado a su uso extensivo y a un aumento de las emisiones a la atmosfera, generando un alto nivel de preocupación ambiental en el ámbito global. Se hace entonces evidente la importancia de un consumo proporcionado de los recursos energéticos y la descarbonización de la economía. Por tanto, cobra sentido la implementación de sistemas de gestión de la energía (SGEn) dentro de las industrias, buscando fomentar el uso racional y eficiente de la energía. En consecuencia, como objetivo de este trabajo se presenta una revisión bibliográfica sobre la integración de los SGEn en la industria, destacando las principales barreras y motivadores para su implementación, enfatizando el rol protagónico que tiene la gerencia dentro de las empresas para convertir estos programas en iniciativas sostenibles en el tiempo. Además, se presenta un análisis del panorama latinoamericano, especialmente el colombiano, sobre la integración de mecanismos para mejorar la eficiencia energética. Uno de los principales resultados evidenciados fue la necesidad de incrementar el apoyo regulatorio de los programas de eficiencia energética en la industria, pues, actualmente, se da un mayor protagonismo a las fuentes de energía renovable que son un paso fundamental para la transición energética, pero deben complementarse con el uso racional y eficiente de los recursos. Aquí, la industria tiene un papel esencial por representar el segmento de usuarios que más energía consume en la matriz energética tradicional.

Palabras clave: Ahorro energético, demanda industrial, eficiencia energética, sistemas de gestión de la energía, transición energética.

1. INTRODUCTION

As global energy development faces challenges such as resource scarcity, environmental pollution, and climate change, promoting the energy transition to renewable sources and achieving green and sustainable development is a common cause in society [

Therefore, the benefits of implementing EE actions extend beyond carbon reduction since it also reduces operating costs, becoming a source of competitive advantage [

Industrial EE can be interpreted as the steps taken by a company to improve its consumption and is often used interchangeably with the term energy management [

Energy is the material basis for human survival and development and is related to the countries' long-term development. Coal, oil, and natural gas are the principal energy sources that promote social progress. But, dependence on these fossil resources limits the scope of the energy transition, and their use increases the carbon footprint of the industrial processes [

From a social point of view, low household income, high energy costs, and energy inefficient buildings directly affect energy poverty. Combining different factors, such as income, increased fuel price regulations, and the use of renewable energy sources can help address these factors. The households' income in vulnerable social groups decreases partially due to the continuous increase in energy costs, which vary due to financial, regulatory, and fiscal policies, and other prevailing conditions [

Thus, this paper reviews the state-of-art related to the challenges and the motivators related to the deployment of energy management systems in the industry. Then, it presents the Latin American panorama (particularly the Colombian one) of energy efficiency in the industrial sector to give a series of general recommendations that would allow the massification of EE and EnMS programs in the industry.

Therefore, this paper reviews the state of the art of energy efficiency and management systems in the Colombian industry, considering a critical and selective point of view oriented to take the elements of greater importance for the Colombian case. The main objective is to generate a conceptual framework based on the best national and international practices for promoting the massification of energy management systems in the industry and the main challenges related to their implementation, giving rise to future research.

2. ENERGY MANAGEMENT SYSTEMS

Limited energy resources and the increase in the consumption of natural resources have generated concern about fossil fuel exploitation and Greenhouse Gas (GHG) emissions, recognizing all the harmful and irremediable effects that these can cause [

Energy efficiency is a term accepted since the 1970s due to the oil crisis, seeking to promote policies for saving energy to avoid an economic crisis due to the high prices of fossil fuels [

For example: while in [

All definitions converge in minimizing consumption without compromising product quality, which is the aim of implementing industrial EnMS. Energy management in industries seeks to ensure and direct management functions to achieve efficient coverage of energy needs in the company [

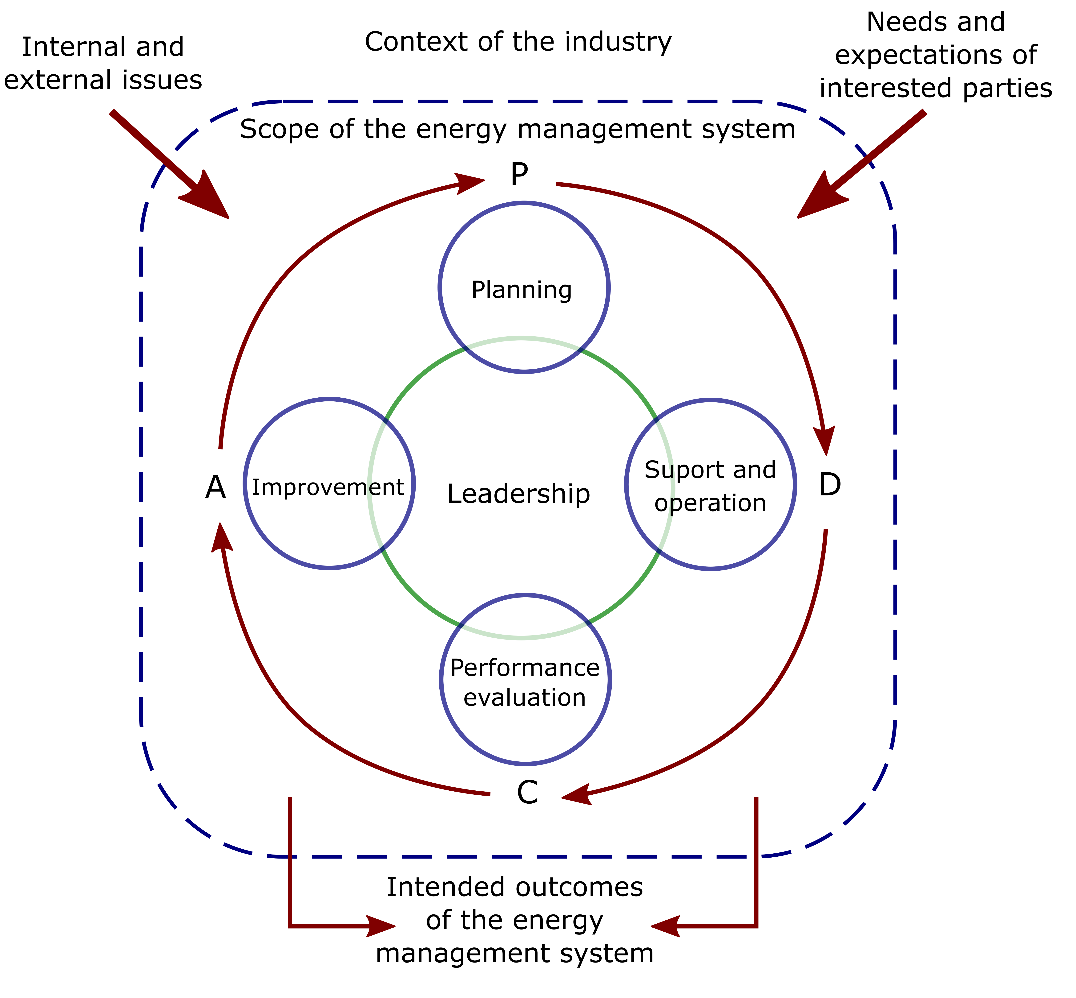

The EE promotes the implementation of the EnMS. Thus, it is essential to know the international recommendations regarding this issue to mold them to the Latin American context and therefore obtain savings in industrial expenses, consumptions and emissions, and increase the rational use of energy [

Here, it is necessary to highlight the possibility of having an EnMS with satisfactory results without having a certification; however, the best results contained in the literature correspond to those EnMS certified in ISO 50001 [

Additionally, organizations seek to be more competitive every day, seeing the need to innovate, increase productivity and reduce losses in their processes. For this reason, there are methodologies based on lean thinking through the multidisciplinary grouping of operational, economic, social, and environmental factors [

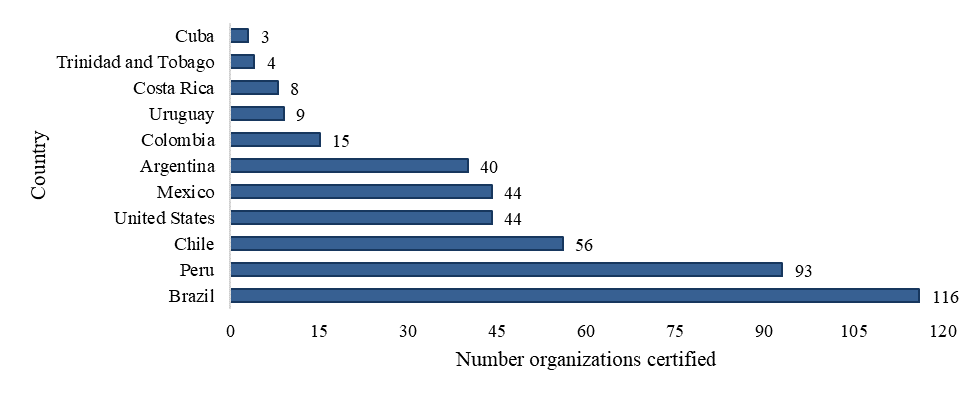

Here, it is essential to note the level of certifications according to IQNet, the certifying entity with worldwide coverage that associates more than 30 national organizations such as AENOR (Spain), AFNOR (France), ANCE, IMNC (Mexico), CCC CSIQ (Italy), CQC (China), D.Q.S. (Germany), D.S. (Denmark), FCAV (Brazil), ICONTEC (Colombia), IRAm (Argentina), AFNOR, CISQ, D.Q.S., NSAI (U.S.A.). In Colombia, there are fifteen (15) companies certified in the NTC-ISO 50001; among them are Intelligent Infrastructure of Siemens S.A., Aguas de Cartagena S.A. E.S.P., National Apprenticeship Service (SENA), Veolia Aguas de Tunja S.A. E.S.P., GENSA SA E.S.P., ITACOL S.A., and Siemens Energy S.A.S. What is notorious is that there are few companies at the national level have international certification, as evidenced in Figure 2 [

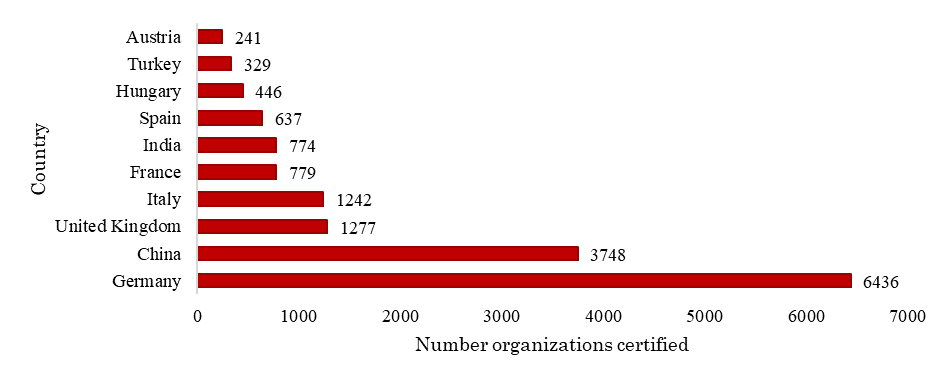

Nevertheless, another is the panorama at the international level, where Germany heads the list of certified organizations with 6 436 certifications, China with 3 748 certifications, and the United Kingdom and Italy with 1 277 and 1 242, respectively, as evidenced in Figure 3. The number of certified organizations in a country reflects the incentives or compensations offered by the government for the inclusion of policies that allow the development of cleaner and more efficient processes [

In this context, it is clear that industrial EnMS implementation is a crucial aspect for reducing GHG emissions and encouraging and accelerating the energy transition; while it allows industries to alleviate losses and inefficiencies. Therefore, it makes sense to list the motivators and challenges of integrating these systems in the industrial sector.

3. FACTORS THAT PROMOTE THE IMPLEMENTATION OF EnMS IN INDUSTRIES

The increase in the demand for electrical energy is a motivator for the EE increase at the international level; forecasts show that demand will continue to increase in the coming decades because the economy is increasingly dependent on the use of energy [

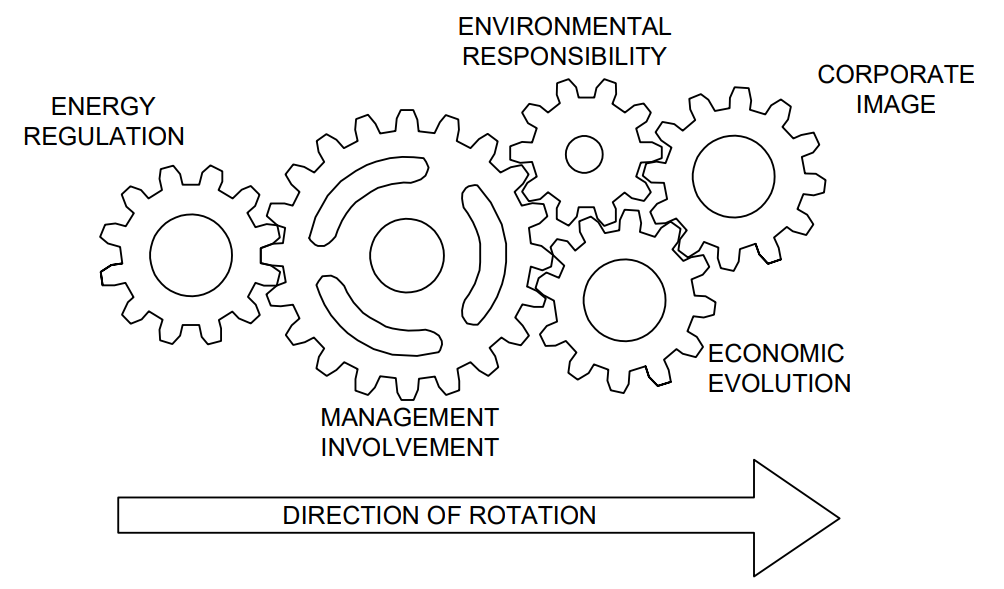

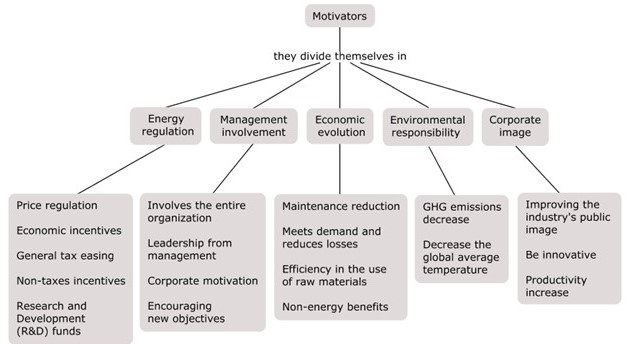

It is clear then that energy regulation is a fundamental factor for the massification of EnMS in the industry, as can be seen in Figure 4 since this is the point in the system that generates the necessary impulse to create a change in the current industrial paradigm because it associates the needs of the country, the characteristics of the industry, and proposes economic motivators that attract the different industrial sectors to the planning and implementation of actions aimed at EE, promoting the participation of management in the deployment of industrial EnMS, motivated by two fundamental factors: (i) the economic evolution of the industries due to the reduction of losses and waste within their processes, obtaining greater profitability and economic evolution, and (ii) the establishment of clean and efficient processes that are environmentally responsible and therefore improve the corporate image of companies that incorporate EnMS into their processes.

To broaden the scope and propose an introduction to the strategies associated with the factors described in Figure 4, Table 1 below shows the main strategies identified to leverage the development of each factor already mentioned.

Source: Created by the authors.

| Factors that promote the implementation of EnMS | Associated strategies |

| Energy regulation | Tax flexibility focused on the efforts to reduce energy consumption [ |

| Management involvement | Commitment of senior management in deploying the EE program [ |

| Environmental responsibility | Monitoring local and global environmental policies [ |

| Economic Evolution | Optimization in equipment maintenance [ |

| Corporate Image | Implementation of certifications in energy management systems (ISO 50001) [ |

In this sense, the aspects that have significant weight in decision-making for the incorporation of alternatives that help improve EE within industries are specified below [

- Government regulation and incentives.

- Participation of management and the energy management team.

- Economic evolution.

- Ecological responsibility and environmental sustainability.

- Improvement of the corporate image and business competitiveness.

These motivators have points of convergence since they are related to each other, as will be seen in the development presented below.

3.1 Government regulation and incentives

Government incentives, through regulation, and stimuli from other institutions are factors to be taken into account by those responsible for making decisions to promote EE measures in the industry, such as the implementation of ISO 50001 [

Therefore, it is necessary to know the policies and incentives that apply to the organization that wants to implement EE methodologies. That is the case in Belgium, Denmark, Switzerland, and the United Kingdom, where a reduction in the payment of the taxes depends on the alignment of the internal EE strategy with the sectoral energy objectives. On the other hand, tax deductions offset the costs of EE investments in Canada, Japan, and the Netherlands [

Both the Japanese and Chinese experiences prove that EE policies slow down the growth of energy consumption and encourage the improvement of EE in the industry [

On another side, in Malaysia, the provision of incentives and programs seeks to promote industrial demand reduction. While, in the Netherlands, subsidies promote the investment in innovative renewable energy technologies and projects [

3.2 Involvement of the energy management team

The implementation of an EnMS implies the commitment of each one of the levels of the organization since it will guarantee greater participation of the teams, and it will motivate the success of the project [

The management has successfully implemented the EnMS when a company involves the staff in the decision-making process and gets them to take ownership of the processes giving valuable contributions and ideas for minimizing losses. When the program's implementation is successful, management must recognize all the staff members involved, increasing the corporative motivation and encouraging new objectives [

3.3 Economic evolution

Energy occupies a crucial position in economic growth [

Unfortunately, non-energy benefits are often omitted in economic analysis, leading to underestimating the total monetary profit of EE projects [

3.4 Ecological responsibility and environmental sustainability

The increase in the global average temperature, the prices of fossil fuels, and the concern about the environmental consequences of GHG emissions are challenges that will affect energy supply and production [

The ecological benefits of implementing EnMS have been identified as one of the primary motivators to deploy these systems [

3.5 Improvement of the corporate image and business competitiveness

In recent decades, globalization and technological change are elements that define the global economic dynamics and shape the behavior of industries that seek to be innovative [

Consequently, increasing productivity is a key motivator [

4. CHALLENGES THAT LIMIT THE WIDESPREAD USE OF ENERGY MANAGEMENT SYSTEMS IN THE INDUSTRY

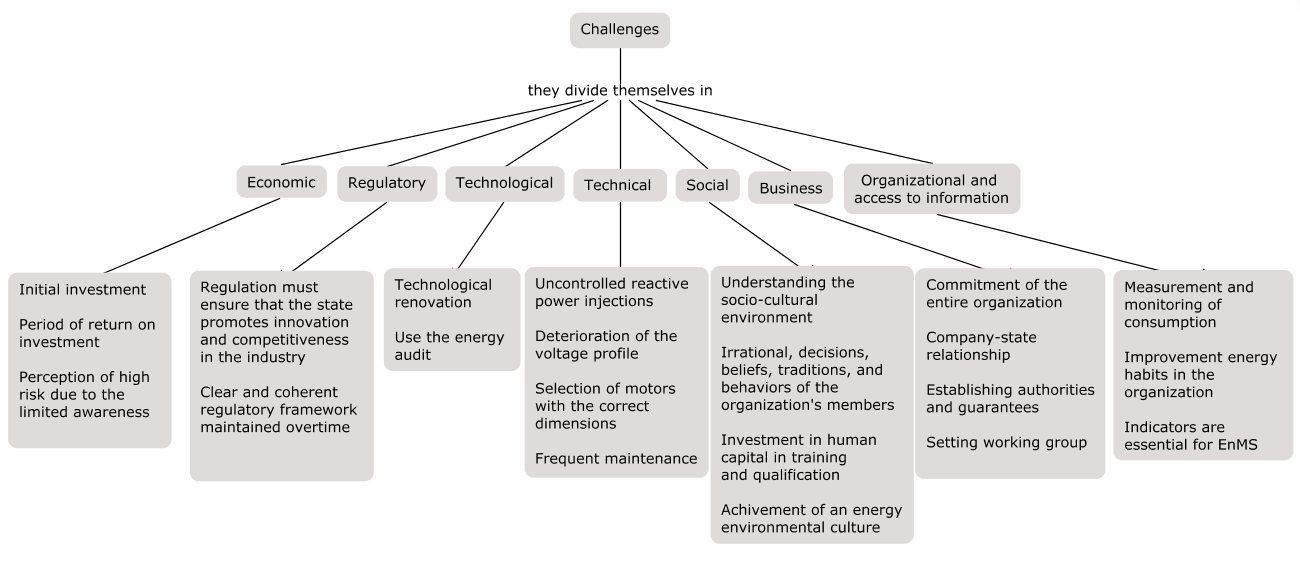

Some barriers limit the implementation of EnMS and prevent their sustainable development. Therefore, it is essential to recognize these barriers [

Next, a classification is presented, which was formed based on different authors and organizations [

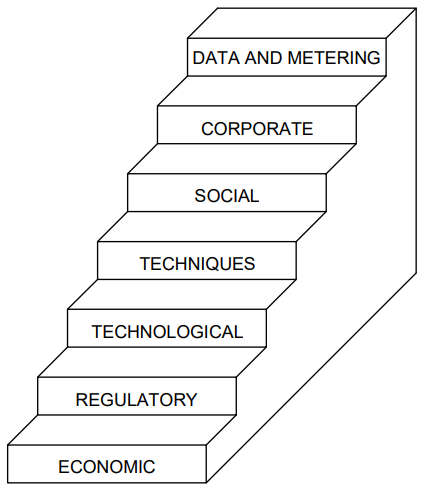

The impact of the barriers in the different industrial sectors is not uniform for all types of industry because they do not have the same magnitude, dimension, and extension. Here, a ladder represents these barriers, as seen in Figure 6. It describes the steps to be overcome for adequately implementing an EnMS within a particular industry.

Some barriers limit the implementation of EnMS and prevent their sustainable development. Therefore, it is essential to recognize these barriers [

The impact of each obstacle in an industry depends on different factors, such as the sector, the processes, the automation level, the method's standardization, and the organizational structure. For this reason, the steps' height will be equivalent to the magnitude of the barrier and the difficulty of overcoming it, and the steps' extension represents the time to overcome it. According to the above, the obstacles magnitudes are different for all industries. The only barrier affecting all sectors is regulatory since regulations are established for each productive sector and not individually for a particular enterprise. This classification analyzes the industry from a technical, technological, social, cultural, and economic point of view to discover the factors that can influence energy inefficiencies.

4.1 Economic barriers

The initial investment for the development of EE projects and the long period of return on investment are fundamental factors when deciding to invest. The last, together with the ignorance of the industrial management about governmental credits and the little economic support, generate a disinterest in the banking entities and creates the perception of high risk due to the limited awareness of the benefits that the EE measures bring. Constituting a significant barrier to the mass use of EnMS [

In this way, another critical factor omitted when proposing projects in EE is the hidden costs, referring to the costs associated with technologies that are not in the initially established investment model [

4.2 Regulatory barriers

The regulation must respond to the reality of each country and the limited resources available to the industry. Energy regulation needs to lead company management to make strategic decisions based on the profits and the perceived performance of the EnMS, establishing commitments and objectives that allow success in its implementation [

According to this, a clear and coherent regulatory framework maintained overtime is necessary as a convenient way to monitor the implemented EE measurements, providing the industry with tools for implementing the EnMS and designating public entities as control bodies [

4.3 Technological barriers

One of the causes of industrial inefficiencies is obsolete and inefficient technology; industries with relatively low efficiency improve by introducing high EE technologies, reducing energy consumption due to losses in their most inefficient processes and equipment. Thus, the technological replacement leads to a decrease in the associated cost for each gross unit produced [

Energy audits are carried out in many cases because the equipment has already completed its useful life. Therefore an audit is needed to determine the most inefficient equipment and processes and to identify if equipment or a process is obsolete [

4.4 Technical barriers

Industries have technical limitations that lead to an increase in inefficiencies, as the case of the uncontrolled reactive power injections, which leads to the reduction in the lines' active power transport capacity, the increase in the losses in the network, and the deterioration of the voltage profile, leading to the decrease in the service quality [

Having high-efficiency equipment and appropriate sizing must be supported in the industry with frequent maintenance. Because, low level of care in the electrical systems is one of the most common causes for the generation of hot spots, due to misalignments in the connections, which raises the temperature of the system, in general, due to the accumulation of dirt in the medium and low voltage installation [

4.5 Social barriers

Understanding the socio-cultural environment is crucial for successfully implementing an EnMS, as this can limit the EE benefits. In the first instance, these barriers are due to the irrational decisions, beliefs, traditions, and behaviors of some members of the organizations without knowledge of EE [

For the successful development of an EnMS, changes in the organizational system are necessary. These changes must involve the planning, in-process control, and decision-making areas; also, keep in mind that support for the EnMS varies due to events such as the energy price and the weight of power in the cost of production [

4.6 Business barriers

The success of an EnMS depends on the commitment of the entire organization, especially management. Without this, it makes no sense to implement the system since this would imply wasted efforts, waste of time, and unsatisfactory results [

For the successful implementation of an EnMS, communication channels must be available so that management is informed about the development of the system and can evidence the risk factors. In addition, a person in charge with technical knowledge must be established, who may be called an energy manager; this person will be in charge of the energy administration in the organization. An adequate EnMS needs to integrate people, procedures, and technologies to optimize the organization's energy performance [

4.7 Organizational barriers and access to information

When implementing measures in EE, attention and importance should be given to the measurement and monitoring of consumption to evaluate the effectiveness of the strategies used to improve energy habits in the organization [

In this way, it is pertinent to consider each indicator's advantages and disadvantages. However, the simultaneous use of various indications can compensate for their weaknesses; this leads to the fact that with multiple hands used together, a comprehensive evaluation can be developed [

Next, Figure 7 exposes the criteria associated with each factor that limits the massification of EnMS in the industry.

5. THE ECONOMY AND INDUSTRY IN THE WORLD WITHIN THE FRAMEWORK OF THE COVID - 19 PANDEMIC

The COVID-19 pandemic has forced worldwide governments to adopt measures to restrict mobility and agglomeration to mitigate the impacts of this virus on the health of its inhabitants. As a result of these measures, a hard smash hit the economy of the countries and global trade [

For 2021, world output growth of 5.2 % is forecast, driven by emerging economies, whose rebound would be above that of developed economies [

Throughout 2020, Latin America experienced a sharp drop in the economy, consumption, investment, and exports, and a contraction in critical sectors due to the COVID-19 pandemic. The most significant decline in economic activity occurred in the second quarter of 2020. As of the third quarter, the GDP of Latin America has begun to recover from the low level of the second quarter. However, it continued to show a negative annual variation rate. After registering a fall of 15.35 % per year in the second quarter of 2020, the third quarter GDP contracted at 7.36 % [

South American economies fell in the first three quarters at a rate of 7.7 % year-on-year, which compares with near-zero growth in the same period a year earlier. For their part, Central American economies have slowed down to the third quarter of 2020 by nine percentage points, going from a growth of 3.2 % in the first three quarters of 2019 to a fall of 5.9 % in the same period in 2020. In the Central America plus Mexico case, the drop in growth until the third quarter of 2020 is 9.2%, which is 9.6 % points lower than the same period in 2019 [

Particularly in Colombia, currently, there is an unpromising outlook for Colombian industry since, according to the national development plan, only 22 % of companies are considered innovative, the relationship between industry and the university was 2.7 % for the year 2016 [

The Economic Commission for Latin America and the Caribbean (ECLAC) presented on December 16, 2020, its traditional Preliminary Balance of the Economies of Latin America, and the Caribbean. This balance ensures that the continent was the most affected region, to such an extent that it classifies the pandemic as the worst economic crisis of the last 120 years [

Therefore, the difficulties in the industry because of the pandemic should lead each sector to seek ways to reduce costs, for which the reduction of surplus production is a crucial factor. Considering the above, the EnMS has advantages that the industry can use in the region since they ensure the optimization of processes, reduction of waste, and increased production efficiency. These aspects are vital to promoting economic development and pushing the industry out of the crisis.

5.1 Colombia and the massification of energy management systems in the framework of the COVID-19 pandemic

Energy consumption in the industrial and commercial sectors at a global level causes around 40 % of GHG emissions; reducing this consumption is decisive for countries to meet their commitments to reduce emissions into the atmosphere [

The massification of the ISO standard depends on the environmental, economic, and sociocultural factors of each region, country, and industrial sector [

However, factors such as the characterization of the demand made in [

Colombia has a strong track record in energy management, from the University - Company - State strategy [

On the other hand, in 2007, the Comprehensive Energy Management model was developed, which would give rise to the Comprehensive Energy Management System. Thanks to this background, the National Strategic Program for Comprehensive Energy Management Systems was planned and developed between 2010 and 2013, led by RECIEE, and through which it was possible to implement 12 EnMS in companies nationwide [

In this way, as a consequence of the energy transition and the national trajectory in EE, regulatory incentives have been created, where Law 1715 of 2014 highlights [

Regarding the technology used in the country, the results of the Useful Energy Balance (BEU) compare the energy consumed by the technologies currently used in Colombia and the consumption if industries use the best available technologies in the national and international market; these are called "Best Available Technologies" (BAT). The results show that in Colombia, useful energy represents 31 % of the final energy; in addition, inefficiency in consumption is around 67 %, which costs the country between 6 600 and 11 000 million USD per year. From the point of view of efficiency in the industry, the final energy could decrease by 71 000 TJ and 97 000 TJ, achieving savings of the order of 810 million USD and 1 400 million USD measuring BAT national and BAT international, respectively [

In addition, the industrial sector had a participation of 11-14 % of the GDP between 1994 and 2014 [

Preventive isolation and the consequent closure of various activities have had a notable impact on the functioning of the Colombian economy and, therefore, on energy consumption. With this decrease in energy demand, forecasts show that the levels of energy consumption registered before COVID-19 could be reached and exceeded between 2020 and August 2022, depending on the economy's performance and the adopted measures [

The national projection scenario under conditions before COVID - 19 estimated a growth rate of 2.67 % in demand for electricity from the interconnected national system for 2020 to 2026, and with the pandemic growth rates reduced to a range of 1.75 % and 1.13 %. For maximum power, the results are similar. Before COVID-19, the expected growth rate was 1.67 %; the new scenarios show 0.82 % and 1.46 % growth rates. Projections resulting from the COVID scenarios indicate that, between 2021 and 2024, 2019 consumption levels could be achieved again [

In the Latin American scenario, the countries are very focused on the development of policies that promote care for the environment and reduce the emission of greenhouse gases; these policies have not had a significant impact since the Paris agreement was signed (COP21) in 2015 because the following six years have been the hottest years on record. For this reason, the joint decision to take care of planet earth or suffer all the repercussions associated with climate change is urgent, and it is necessary to develop strategies that allow obtaining results. Although the latest promises were transparent and credible, parties did not entirely fulfill them, which establishes a debt between the most developed and underdeveloped countries because Latin America is one of the most vulnerable regions to climate change. Still, Latin America faces the environmental crisis in a disorganized way since there is no common position to meet this change, and it does not establish common strategies for the region; this was evidenced again at the COP26 in Glasgow [

According to the Worldwide Fund for Nature (WWF) report, Colombia, Panama, Costa Rica, the Dominican Republic, and Suriname have the most ambitious commitments. These guidelines are vital as a route against the climate crisis and formalize each country's responsibilities [

6. CONCLUSIONS

The present work is a review paper, which is the result of the study and the compilation of the best practices and international experiences. This review makes it possible to identify and classify the barriers and motivations related to developing alternatives that increase EE in the industry. The last allows establishing a clear framework that leads to the proposal of solutions and guidelines in EE matters, which are the ideal complement of the massification of non-conventional renewable energy sources to support the energy transition and achieve the energy transformation. Here, it is crucial to highlight those industries with the most intensive energy use have the most significant savings potential; for this reason, energy regulation must provide additional incentives framed in EE without neglecting organizations with lower consumption. In general, the industry's motivators should be reconsidered from the regulatory point of view to have a significant impact at the environmental level.

The most relevant aspects that prevent the massification of EnMS in the Colombian industry are the organizational, cultural, political, and regulatory aspects. Within the organizations, strong leadership is essential for guiding the habits and customs of the organization members towards a culture of saving energy. The last without forgetting that support and encouragement of the senior positions, both in disposition and economical way, is decisive for carrying out a correct exercise in EE. However, the stimuli that public entities offer to companies that decide to implement programs in EE, such as EnMS, have a strong influence on the process. One of the most significant limitations within the national context for the popularization of industrial EnMS is that the management and the most influencer areas in the organization are not aware of the potential benefits of the EnMS implementation, which is aggravated by the common belief of some individuals within the organizations regarding the benefits of the performance of EE programs. Of the most significant limitations within the national context for the popularization of EnMS in the industry.

The EnMS is a vital piece as part of the evolution of the industry towards sustainability and friendliness with the environment; it is necessary to ensure that these initiatives have greater strength to attack one of the main fronts in terms of climate change, such as GHG emissions generated by the industrial sector today.

Within the Colombian context, there is interest on the part of the government to encourage the industrial sector to increase its EE. However, the incentives currently exist in Colombian law for EE programs are insufficient for achieving the mass use of EnMS; for this reason, it is recommended by the energy regulator to provide further scope to initiatives that lead to making it easier for the industry to manage its energy.

7. ACKNOWLEDGMENTS

This work was supported by the Ministerio de Ciencia y Tecnología - Minciencias, through the project "Valoración de los criterios técnicos, económicos y regulatorios para la integración de sistemas de gestión de la energía en la industria y su impacto en las redes de distribución típicas colombianas", which is a beneficiary of call 891 of Minciencias "Fortalecimiento de vocaciones y formación en CTeI para la reactivación económica en el marco de la postpandemia 2020" through “Resolución 1050-Vinculación Jóvenes Investigadores-Sept-17-2021” from Universidad Nacional de Colombia.

CONFLICTS OF INTEREST

The authors declare that they have no conflicts of interest that could inappropriately influence the results obtained or the proposed interpretations.

AUTHOR CONTRIBUTIONS

All authors have contributed substantially to the writing of the paper. The first two authors were the main ones in charge of compiling the primary sources of information (research papers, norms, standards, and books, among others) for the establishment of this bibliographic review currently presented. They were the main ones responsible for the initial writing. All four authors extensively revised the document, made significant changes, summarized, and removed redundant or unnecessary information. The third and fourth authors were responsible for translating to English and final editing the document.

8. REFERENCES

- arrow_upward [1] R. Wang, Q. Wang, S. Yao, “Evaluation and difference analysis of regional energy efficiency in China under the carbon neutrality targets: Insights from DEA and Theil models”, J. Environ. Manage., vol. 293, p. 112958, Sep. 2021. https://doi.org/10.1016/j.jenvman.2021.112958

- arrow_upward [2] K. M. Smith, S. Wilson, M. E. Hassall, “Could focusing on barriers to industrial energy efficiency create a new barrier to energy efficiency?”, J. Clean. Prod., vol. 310, p. 127387, Aug. 2021. https://doi.org/10.1016/j.jclepro.2021.127387

- arrow_upward [3] Organización de Naciones Unidas - ONU, Guía Práctica para la Implementación de un Sistema de Gestión de la Energía, 2015.

- arrow_upward [4] W. Li et al., “Nexus between energy poverty and energy efficiency: Estimating the long-run dynamics”, Resour. Policy, vol. 72, p. 102063, Aug. 2021. https://doi.org/10.1016/j.resourpol.2021.102063

- arrow_upward [5] C. A. Gameros Morales, S. P. Paredes Araiza, C. H. Carmona Jurado, “Sistema de gestión energética, práctica como beneficio económico y ambiental en organizaciones”, FINGUACH, vol. 5, no. 17, pp. 3-5, Sep. 2018. https://vocero.uach.mx/index.php/finguach/article/view/356

- arrow_upward [6] G. Valencia, K. N. Rodriguez, G. R. Torregroza Matos, C. Acevedo, J. Duarte Forero, “Implementation of the ISO 50001 standard to sustainable energy and economic saving the industrial sector”, Sci. Tech., vol. 25, no. 2, pp. 261–268, Jun. 2020. https://doi.org/10.22517/23447214.23541

- arrow_upward [7] R. Fouquet, “Historical energy transitions: Speed, prices and system transformation”, Energy Res. Soc. Sci., vol. 22, pp. 7-12, Dec. 2016. https://doi.org/10.1016/j.erss.2016.08.014

- arrow_upward [8] Unidad de Planeación Minero Energética - UPME, “Plan Energético Nacional 2020-2050. La transformación energética que habilita el desarrollo sostenible”, 2020.

- arrow_upward [9] R. Xing, T. Hanaoka, Y. Kanamori, T. Masui, “Greenhouse gas and air pollutant emissions of China’s residential sector: The importance of considering energy transition”, Sustain., vol. 9, no. 4, pp. 1–17, Apr. 2017. https://doi.org/10.3390/su9040614

- arrow_upward [10] C. Liao, J. T. Erbaugh, A. C. Kelly, A. Agrawal, “Clean energy transitions and human well-being outcomes in Lower and Middle Income Countries: A systematic review”, Renew. Sustain. Energy Rev., vol. 145, p. 111063, Jul. 2021. https://doi.org/10.1016/j.rser.2021.111063

- arrow_upward [11] E. Nam, T. Jin, “Mitigating carbon emissions by energy transition, energy efficiency, and electrification: Difference between regulation indicators and empirical data”, J. Clean. Prod., vol. 300, p. 126962, Jun. 2021. https://doi.org/10.1016/j.jclepro.2021.126962

- arrow_upward [12] D. Rojas Rodríguez, O. Prías, “Herramientas Lean para apoyar la implementación de Sistemas de Gestión de la Energía basados en ISO 50001”, Energética, no. 44, pp. 49–60, Jul. 2014.

- arrow_upward [13] V. Dufresne, P. Langlois, M. Couture-Roy, S. Flamand, Diseño de programas de eficiencia energética, New York: Banco Interam. Desarro., 2013.

- arrow_upward [14] S. Brullot, G. Junqua, B. Zuindeau, “Écologie Industrielle Et Territoriale À L’Heure De La Transition Écologique Et Sociale De L’Économie”, Rev. d’Économie Régionale Urbaine, no. 5, p. 771-796, Dec. 2017. https://doi.org/10.3917/reru.175.0771

- arrow_upward [15] J. Vanegas, S. Botero, “Eficiencia energética en microempresas de Medellín: un estudio de valoración de barreras”, Lect. Econ., no. 77, Jul. 2012.

- arrow_upward [16] J. Sánchez, A. Blanco, A. Yépez, M. Coviello, A. Schunschny, R. G. Aiello, Eficiencia Energética en América Latina y el Caribe: Avances y oportunidades, Banco Interamericano de Desarrollo, 2017.

- arrow_upward [17] M. Poveda, Eficiencia Energética: Recurso no aprovechado, 2007. https://biblioteca.olade.org/opac-tmpl/Documentos/old0054.pdf

- arrow_upward [18] C. Pérez Tristancho, F. Vera Méndez, “Fundamentos para la administración energética en la industria Colombiana a través de indicadores de gestión”, Sci. Tech., vol. 2, no. 50, pp. 57–66, Apr. 2012. https://doi.org/10.22517/23447214.1557

- arrow_upward [19] N. V. Blanco-Orozco, “Modelo de gestión de la energía eléctrica con base en indicadores (MGEI), para empresas generadoras con sistemas de cogeneración en Nicaragua”, Rev. Tecnol. en Marcha, vol. 31, no. 3, pp. 15-28, Jul. 2018. https://doi.org/10.18845/tm.v31i3.3898

- arrow_upward [20] M. G. Patterson, “What is energy efficiency? Concepts, indicators and methodological issues”, Ener. Pol., vol. 24, no. 5, pp. 377–390, May. 1996. https://doi.org/10.1016/0301-4215(96)00017-1

- arrow_upward [21] C. Méndez-Rodríguez, C. F. Rengifo-Rodas, J. C. Corrales-Muñoz, A. Figueroa-Casas, “Systematic review of energy efficiency (E.E.). Basis for an alternative vision of E.E. in Colombia,” Sci. Tech., vol. 25, no. 2, pp. 329–336, Jun. 2020. https://doi.org/10.22517/23447214.24449

- arrow_upward [22] D. Vanham, H. Medarac, J. F. Schyns, R. J. Hogeboom, D. Magagna, “The consumptive water footprint of the European Union energy sector”, Environ. Res. Lett., vol. 14, no. 10, Oct. 2019. https://doi.org/10.1088/1748-9326/ab374a

- arrow_upward [23] O. F. Prias Caicedo, J. C. Campos Avella, D. B. Rojas Rodríguez, A. Palencia Salas, Implementación de un sistema de Gestión de la Energía. Guía con base en la norma ISO 50001, 2nd ed. 2019.

- arrow_upward [24] P. Antunes, P. Carreira, M. Mira da Silva, “Towards an energy management maturity model”, Energy Policy, vol. 73, pp. 803–814, Oct. 2014. https://doi.org/10.1016/j.enpol.2014.06.011

- arrow_upward [25] R. Castrillón, F. J. Rey, O. Puente, “El Establecimiento de Líneas de Bases Energéticas Según ISO 50001. Una Contribución a la Producción más Limpia en la Industria”, 7th Acad. Int. Work. Adv. Clean. Prod., pp. 1-10, Jun. 2018.

- arrow_upward [26] A. McKane et al., “Predicting the quantifiable impacts of ISO 50001 on climate change mitigation”, Energy Policy, vol. 107, pp. 278-288, Aug. 2017. https://doi.org/10.1016/j.enpol.2017.04.049

- arrow_upward [27] F. Marimon, M. Casadesús, “Reasons to adopt ISO 50001 Energy Management System”, Sustain., vol. 9, no. 10, pp. 1-15, Sep. 2017. https://doi.org/10.3390/su9101740

- arrow_upward [28] International Organization for Standardization, “ISO 50001: Guía De Implantación De Sistemas De Gestión De La Energía”, 2011.

- arrow_upward [29] M. F. Carmada, “Just-in-time y eficiencia energetica: implicancias en los sistemas de gestion de la energia y procesos de descarbonizacion de sistemas industriales”, Rev. Esc. Perfec. Inv. Ope., vol. 28, no. 48 pp. 58–77, Nov. 2020.

- arrow_upward [30] R. Henao, W. Sarache, I. Gómez, “Lean manufacturing and sustainable performance: Trends and future challenges”, J. Clean. Prod., vol. 208, pp. 99–116, Jan. 2019. https://doi.org/10.1016/j.jclepro.2018.10.116

- arrow_upward [31] ISO, “The ISO Survey of Management System Standard Certifications – 2020 – Explanatory Note”, https://isotc.iso.org/livelink/livelink?func=ll&objId=18808772&objAction=browse&viewType=1

- arrow_upward [32] M.-J. Li, W.-Q. Tao, “Review of methodologies and polices for evaluation of energy efficiency in high energy-consuming industry”, Appl. Energy, vol. 187, pp. 203–215, Feb. 2017. https://doi.org/10.1016/j.apenergy.2016.11.039

- arrow_upward [33] A. Z. Zurkafli, N. Zaini, M. F. A. Latip, “Personal Energy Auditor based on Energy Consumption Rating using Normal Distribution for Energy Efficiency”, in Proc. - 10th IEEE Int. Conf. Control Syst. Comput. Eng. ICCSCE 2020, Penang, 2020, pp. 119-124. https://doi.org/10.1109/ICCSCE50387.2020.9204942

- arrow_upward [34] A. Olivares, “La seguridad energética en la Unión Europea: ¿un modelo a imitar?”, Estud. Int., vol. 49, no. 187, pp. 43-84, Aug. 2017.

- arrow_upward [35] E. Cagno, A. Trianni, “Exploring drivers for energy efficiency within small- and medium-sized enterprises: First evidences from Italian manufacturing enterprises”, Appl. Energy, vol. 104, pp. 276–285, Apr. 2013. https://doi.org/10.1016/j.apenergy.2012.10.053

- arrow_upward [36] K. Tanaka, “Review of policies and measures for energy efficiency in industry sector”, Energy Policy, vol. 39, no. 10, pp. 6532-6550, Oct. 2011. https://doi.org/10.1016/j.enpol.2011.07.058

- arrow_upward [37] M. de Laire, Y. Fiallos, Á. Aguilera, Beneficios de los sistemas de gestión de energía, basados en ISO 50001 y casos de éxito, 2017. https://guiaiso50001.cl/guia/wp-content/uploads/2017/05/Casos_exito_correccion9.pdf

- arrow_upward [38] U.S. Congress, “The Energy Policy Act 2005,” Energy Policy, 2005.

- arrow_upward [39] Comision Europea, “Nuevas etiquetas energéticas de la Unión aplicables a partir del 1 de marzo de 2021”, 2021. https://ec.europa.eu/commission/presscorner/detail/es/ip_21_818

- arrow_upward [40] F. & R. A. (DEFRA) Department for Environment, “Framework for the UK emissions trading scheme, United Kingdom,” pp. 1–55. https://www.gov.uk/government/publications/participating-in-the-uk-ets/participating-in-the-uk-ets

- arrow_upward [41] A. V. H. Sola, C. M. M. Mota, “Influencing factors on energy management in industries”, J. Clean. Prod., vol. 248, p. 119263, Mar. 2020. https://doi.org/10.1016/j.jclepro.2019.119263

- arrow_upward [42] D. Bravo Hidalgo, Y. Martínez Perez, “Eficiencia energética, competitividad empresarial y economía verde.”, Rev. Publicando, vol. 3, no. 9, pp. 447-466, 2016.

- arrow_upward [43] A. J. H. Nel, J. C. Vosloo, M. J. Mathews, “Financial model for energy efficiency projects in the mining industry”, Energy, vol. 163, pp. 546-554, Nov. 2018. https://doi.org/10.1016/j.energy.2018.08.154

- arrow_upward [44] J. Malinauskaite, H. Jouhara, B. Egilegor, F. Al-Mansour, L. Ahmad, M. Pusnik, “Energy efficiency in the industrial sector in the EU, Slovenia, and Spain”, Energy, vol. 208, p. 118398, Oct. 2020. https://doi.org/10.1016/j.energy.2020.118398

- arrow_upward [45] Red colombiana de conocimiento en eficiencia energetica - RECIEE, “Sistemas De Gestión Integral De La Energía Sgie”, p. 36, 2008.

- arrow_upward [46] H. Fuchs, A. Aghajanzadeh, P. Therkelsen, “Identification of drivers, benefits, and challenges of ISO 50001 through case study content analysis”, Energy Policy, vol. 142, p. 111443, Jul. 2020. https://doi.org/10.1016/j.enpol.2020.111443

- arrow_upward [47] G. Mejía, “Estudio comparativo entre la legislación de eficiencia energética de Colombia y España”, Rev. EAN, no. 77, 2014. https://doi.org/10.21158/01208160.n77.2014.819

- arrow_upward [48] K. Lo, “A critical review of China’s rapidly developing renewable energy and energy efficiency policies”, Renew. Sustain. Energy Rev., vol. 29, pp. 508–516, Jan. 2014. https://doi.org/10.1016/j.rser.2013.09.006

- arrow_upward [49] Y. Zhao et al., “A comparative study of energy consumption and efficiency of Japanese and Chinese manufacturing industry”, Energy Policy, vol. 70, pp. 45–56, Jul. 2014. https://doi.org/10.1016/j.enpol.2014.02.034

- arrow_upward [50] Unidad de Planeación Minero Energética ─ UPME. “Camino a la transformación: Colombia le apuesta a la eficiencia energética industrial, una ruta segura y efectiva para hacerle frente al cambio climático,” Semana Sostenible, vol. 0, no. 24, pp. 379–394, 2011. https://www1.upme.gov.co/DemandaEnergetica/EEIColombia/Semana_EEI_Colombia.pdf

- arrow_upward [51] M. Pusnik, F. Al-Mansour, B. Sucic, A. F. Gubina, “Gap analysis of industrial energy management systems in Slovenia”, Energy, vol. 108, pp. 41–49, Aug. 2016. https://doi.org/10.1016/j.energy.2015.10.141

- arrow_upward [52] B. Kruyt, D. P. van Vuuren, H. J. M. de Vries, H. Groenenberg, “Indicators for energy security”, Energy Policy, vol. 37, no. 6, pp. 2166–2181, Jun. 2009. https://doi.org/10.1016/j.enpol.2009.02.006

- arrow_upward [53] R. Wang, H. Zhang, F. Shi, Y. Zhang, L. Zhang, “Empirical Study of the Relationship between Global Energy consumption and economic growth”, China International Electrical and Energy Conference (CIEEC), Beijing, 2017, pp. 394-399. https://doi.org/10.1109/CIEEC.2017.8388480

- arrow_upward [54] M. Stamenic, N. Tanasić, T. Simonović, A. Nikolić, “Energy management system for energy efficiency improvement in the industrial sector of the republic of Serbia”, in 4th Int. Symp. Environ. Friendly Energies Appl. EFEA, Belgrade, 2016, pp. 1-4. https://doi.org/10.1109/EFEA.2016.7748821

- arrow_upward [55] D. M. Carabalí, C. R. Forero, Y. Cadavid, “Energy diagnosis and structuring an energy saving proposal for the metal casting industry: An experience in Colombia”, Appl. Therm. Eng., vol. 137, pp. 767–773, Jun. 2018. https://doi.org/10.1016/j.applthermaleng.2018.04.012

- arrow_upward [56] M. T. Johansson, P. Thollander, “A review of barriers to and driving forces for improved energy efficiency in Swedish industry– Recommendations for successful in-house energy management”, Renew. Sustain. Energy Rev., vol. 82, Part. 1, pp. 618–628, Feb. 2018. https://doi.org/10.1016/j.rser.2017.09.052

- arrow_upward [57] A. Kamal, S. G. Al-Ghamdi, M. Koc, “Revaluing the costs and benefits of energy efficiency: A systematic review”, Energy Res. Soc. Sci., vol. 54, pp. 68–84, Aug. 2019. https://doi.org/10.1016/j.erss.2019.03.012

- arrow_upward [58] Ministerio de Minas y Energías, Unidad de Planeación Minero Energética – UPME, Organización de las Naciones Unidas para el Desarrollo Industrial - ONUDI, “Informe de Impacto Programa EEI Colombia Agosto 2019”, Ago. 2019. https://www1.upme.gov.co/DemandayEficiencia/Documents/Proyecto_EE_industrial/Impacto_proyecto_EEI.pdf

- arrow_upward [59] J. L. Samaniego, L. M. Galindo, S. J. Mostacedo, J. Ferrer Carbonell, J. E. Alatorre, O. Reyes, El Cambio Climático y el Sector de Energía en América Latina, CEPAL, Nac. Unidas, 2017.

- arrow_upward [60] S. Abolhosseini, A. Heshmati, J. Altmann, “A Review of Renewable Energy Supply and Energy Efficiency Technologies”, IZA Discuss. Pap., no. 8145, Apr. 2014. https://docs.iza.org/dp8145.pdf

- arrow_upward [61] D. Apriyanti, B. Warsito, T. Prasetyo, “Creating green industry through the implementation of an energy management system: Case study at PT. X”, in 4th IEEE Conf. Power Eng. Renew. Energy, ICPERE, Solo, 2018, pp. 1-5. https://doi.org/10.1109/ICPERE.2018.8739493

- arrow_upward [62] J. A. Nieves, A. J. Aristizábal, I. Dyner, O. Báez, D. H. Ospina, “Energy demand and greenhouse gas emissions analysis in Colombia: A LEAP model application”, Energy, vol. 169, pp. 380–397, Feb. 2019. https://doi.org/10.1016/j.energy.2018.12.051

- arrow_upward [63] M. E. Gómez Rodríguez, M. L. Villalba Morales, D. M. Pérez Valencia, “Análisis comparativo de las capacidades de innovación tecnológica de la industria manufacturera colombiana, 2006-2014. Una revisión a partir de la metodología de clases latentes”, Innovar, vol. 30, no. 77, pp. 93–106, Jul. 2020. https://doi.org/10.15446/innovar.v30n77.87451

- arrow_upward [64] American Council for an Energy-Efficient Economy, “Energy Efficiency and Economic Opportunity”. https://www.aceee.org/fact-sheet/ee-and-economic-opportunity

- arrow_upward [65] D. Ürge-Vorsatz, E. Wójcik-Gront, S. Tirado Herrero, E. Labzina, P. Foley, Employment Impacts of a Large ‐ Scale Deep Building Energy Retrofit Programme in Poland, European Climate Foundation, 2012.

- arrow_upward [66] P. Thollander, S. Backlund, A. Trianni, E. Cagno, “Beyond barriers - A case study on driving forces for improved energy efficiency in the foundry industries in Finland, France, Germany, Italy, Poland, Spain, and Sweden”, Appl. Energy, vol. 111, pp. 636–643, Nov. 2013. https://doi.org/10.1016/j.apenergy.2013.05.036

- arrow_upward [67] D. Lee, C. C. Cheng, “Energy savings by energy management systems: A review”, Renew. Sustain. Energy Rev., vol. 56, pp. 760–777, Apr. 2016. https://doi.org/10.1016/j.rser.2015.11.067

- arrow_upward [68] O. Prias, D. Montaña, “Modelo estratégico de innovación para impulsar la gestión energética en Colombia”, Energética, vol. 44, pp. 61–68, Sep. Dic. 2014.

- arrow_upward [69] J. Henriques, J. Catarino, “Motivating towards energy efficiency in small and medium enterprises”, J. Clean. Prod., vol. 139, pp. 42–50, Dec. 2016. https://doi.org/10.1016/j.jclepro.2016.08.026

- arrow_upward [70] G. Corredor, “Colombia y la transición energética”, Cienc. Política, vol. 13, no. 25, pp. 107–125, Ene. 2018. https://doi.org/10.15446/cp.v12n25.70257

- arrow_upward [71] J. Cabrera, G. Araujo, E. Chérrez, M. Bernal, W. Lucero, R. Parrales, “Eficiencia energética en el sector industrial en media y alta tensión. Caso de estudio Cuenca”, YACHANA Rev. Científica, vol. 5, no. 3, pp. 48–60, 2016.

- arrow_upward [72] R. Manrique, D. Vásquez, G. Vallejo, F. Chejne, A. A. Amell, B. Herrera, “Analysis of barriers to the implementation of energy efficiency actions in the production of ceramics in Colombia”, Energy, vol. 143, pp. 575–584, Jan. 2018. https://doi.org/10.1016/j.energy.2017.11.023

- arrow_upward [73] E. Giacone, S. Mancò, “Energy efficiency measurement in industrial processes”, Energy, vol. 38, no. 1, pp. 331–345, Feb. 2012. https://doi.org/10.1016/j.energy.2011.11.054

- arrow_upward [74] P. Schönsleben, M. Vodicka, K. Bunse, F. O. Ernst, “The changing concept of sustainability and economic opportunities for energy-intensive industries”, CIRP Ann., vol. 59, no. 1, pp. 477–480, 2010. https://doi.org/10.1016/j.cirp.2010.03.121

- arrow_upward [75] J. Fresner, F. Morea, C. Krenn, J. Aranda Uson, F. Tomasi, “Energy efficiency in small and medium enterprises: Lessons learned from 280 energy audits across Europe”, J. Clean. Prod., vol. 142, Part. 4, pp. 1650–1660, Jan. 2017. https://doi.org/10.1016/j.jclepro.2016.11.126

- arrow_upward [76] G. E. Gancino Bustamante, Análisis de escenarios de la energía del sector industrial del Ecuador, Quito: UCE 2018. http://www.dspace.uce.edu.ec/handle/25000/16663

- arrow_upward [77] J. A. Rosero G., S. M. Téllez G., O. F. Prias C., “Gestión energética integral en procesos industriales”, Revista Visión Electrónica., vol. 7, no. 2, pp. 175–184, Dic. 2013.

- arrow_upward [78] C. G. Zapata-Garza, M. Demmler, “Panorama del Sistema de Gestión Energética como valor compartido en las empresas mexicanas”, Ciencias Adm. Teoría y Prax., vol. 13, no. 2, pp. 54–67, Jul. 2017. https://cienciasadmvastyp.uat.edu.mx/index.php/ACACIA/article/view/90

- arrow_upward [79] P. Ravillard, F. Carvajal, D. D. López Soto, J. E. Chueca, K. Antonio, Y. Ji, M. Carvalho Metanias Halllak, “Towards Greater Energy Efficiency in Latin America and the Caribbean: Progress and Policies”, Inter - American Development Bank, 2019. https://doi.org/10.18235/0002070

- arrow_upward [80] J. Malinauskaite, H. Jouhara, L. Ahmad, M. Milani, L. Montorsi, M. Venturelli, “Energy efficiency in industry: EU and national policies in Italy and the UK”, Energy, vol. 172, pp. 255–269, Apr. 2019. https://doi.org/10.1016/j.energy.2019.01.130

- arrow_upward [81] S. Z. Abbas, A. Kousar, S. Razzaq, A. Saeed, M. Alam, A. Mahmood, “Energy management in South Asia”, Energy Strateg. Rev., vol. 21, pp. 25–34, Aug. 2018. https://doi.org/10.1016/j.esr.2018.04.004

- arrow_upward [82] M. A. Bermeo-Ayerbe, C. Ocampo-Martínez, J. Diaz-Rozo, “Adaptive predictive control for peripheral equipment management to enhance energy efficiency in smart manufacturing systems”, J. Clean. Prod., vol. 291, p. 125556, Apr. 2021. https://doi.org/10.1016/j.jclepro.2020.125556

- arrow_upward [83] D. Saygin, E. Worrell, M. K. Patel, D. J. Gielen, “Benchmarking the energy use of energy-intensive industries in industrialized and in developing countries”, Energy, vol. 36, no. 11, pp. 6661–6673, Nov. 2011. https://doi.org/10.1016/j.energy.2011.08.025

- arrow_upward [84] B. Pérez, “La Unión Europea en la transición hacia la neutralidad climática: Retos y estrategias en la implementación del Acuerdo de París”, Rev. Española Derecho Int., vol. 72, no. 2, pp. 117–141, 2020.

- arrow_upward [85] Comisión de Regulación de Energía y Gas - CREG, “Gestión del Flujo de Potencia Reactiva”, 2005.

- arrow_upward [86] M. J. S. Zuberi, A. Tijdink, M. K. Patel, “Techno-economic analysis of energy efficiency improvement in electric motor driven systems in Swiss industry”, Appl. Energy, vol. 205, pp. 85–104, Nov. 2017. https://doi.org/10.1016/j.apenergy.2017.07.121

- arrow_upward [87] M. Apaza Tapia, “Estudio De Control Y Disminución De Pérdidas Dentro Del Servicio Eléctrico Puno Alimentador 101 - Concesión Eléctrica De Electropuno S.A.A.”, 2017. http://repositorio.unap.edu.pe/handle/UNAP/7044

- arrow_upward [88] Ministerio de Minas y energía Colombia, Plan de Acción Indicativo de Eficiencia Energética 2017-2022: una realidad y oportunidad para Colombia, 2016. http://www1.upme.gov.co/DemandaEnergetica/MarcoNormatividad/PAI_PROURE_2017-2022.pdf

- arrow_upward [89] J. C. Campos Avella, O. F. Prías Caicedo, E. C. Quispe Oqueña, J. R. Vidal Medina, E. D. Lora Figueroa, “El MGIE, un Modelo de Gestión Energética Para El Sector Productivo Nacional”, El Hombre y la Maquina, no. 30, pp. 18–31, Ene. 2008.

- arrow_upward [90] F. Alvarez, H. Rudnick, “Impact of energy efficiency incentives on electricity distribution companies”, IEEE Trans. Power Syst., vol. 25, no. 4, pp. 1865–1872, Nov. 2010. https://doi.org/10.1109/TPWRS.2010.2045162

- arrow_upward [91] Corporación de Soluciones Energéticas Integrales - Cosenit SA, Unidad de Planeación Minero Energética - UPME, “Estrategia de uso racional de energía en el sector industrial en Colombia”, 2004.

- arrow_upward [92] P. Bandarra, M. T. Valdez, A. Pereira, “Solutions for monitoring and analysing for energy consumption - Energy management systems”, in Proc. 51st Int. Univ. Power Eng. Conf. UPEC, Coimbra, 2016, pp. 1-5. https://doi.org/10.1109/UPEC.2016.8114051

- arrow_upward [93] C. Song et al., “Research on energy efficiency evaluation based on indicators for industry sectors in China”, Appl. Energy, vol. 134, pp. 550–562, Dec. 2014. https://doi.org/10.1016/j.apenergy.2014.08.049

- arrow_upward [94] J. Uribe-Hernández, L. Ávila-Roa, E. A. Chacón-Ramírez, “Sistema de gestión de energía bajo el paradigma de Industria 4.0”, Rev. Ingenio, vol. 18, no. 1, pp. 33–40, Ene. 2021. https://doi.org/10.22463/2011642x.2780

- arrow_upward [95] Unidad de Planeación Minero Energética ─ UPME, Proyección Demanda de Energéticos Ante El Covid 19 2020 - 2026, 2020. http://www.siel.gov.co/siel/documentos/documentacion/Demanda/UPME_Proyeccion_Demanda_Energia_Junio_2020.pdf

- arrow_upward [96] J. L. Clavellina Miller, M. I. Domínguez Rivas, “Implicaciones económicas de la pandemia por COVID-19 y opciones de política”, Inst. Belisario Domínguez, 2020. http://bibliodigitalibd.senado.gob.mx/handle/123456789/4829

- arrow_upward [97] Comisión Económica para América Latina y el Caribe - CEPAL, Balance Preliminar de las Economías de América Latina y el Caribe. 2014. http://repositorio.cepal.org/bitstream/handle/11362/37344/S1420978_es.pdf?sequence=68

- arrow_upward [98] Banco Central Europeo, “Eurosystem staff macroeconomic projections”, 2020. https://www.ecb.europa.eu/pub/projections/html/index.en.html

- arrow_upward [99] L. E. Vallejo Zamudio, “El plan nacional de desarrollo 2018-2022: ‘Pacto por Colombia, pacto por la equidad’”, Apunt. del Cenes, vol. 38, no. 68, Ago. 2019. https://doi.org/10.19053/01203053.v38.n68.2019.9924

- arrow_upward [100] Ministerio del interior de Colombia, “Decreto 457 de 2020”, 2020.

- arrow_upward [101] Asociación Nacional de Empresarios de Colombia - ANDI, “Colombia: Balance 2020 Y Perspectivas 2021”, 2021.

- arrow_upward [102] J. Yánez, R. Yánez, “Auditorías, mejora continua y normas ISO: factores clave para la evaluación de las organizaciones”, Ing. Ind. Actual. y Nuevas Tendencias, vol. 3, no. 9, pp. 83-92, Jul. 2012. https://www.redalyc.org/pdf/2150/215026158006.pdf

- arrow_upward [103] J. M. Sousa Lira, E. G. Salgado, L. A. Beijo, “Which factors does the diffusion of ISO 50001 in different regions of the world is influenced?”, J. Clean. Prod., vol. 226, pp. 759–767, Jul. 2019. https://doi.org/10.1016/j.jclepro.2019.04.127

- arrow_upward [104] Organización de las Naciones Unidas para el Desarrollo Industrial - ONUDI, Unidad de Planeación Minero Energética - UPME, “Informe de Impacto Programa EEI Colombia Agosto 2019”, 2019. https://www1.upme.gov.co/DemandaEnergetica/EEIColombia/Impacto_proyecto_EEI.pdf

- arrow_upward [105] J. D. Beltrán Gallego, M. Quintero Ríos, D. López García, S. X. Carvajal Quintero, “Desafíos y recomendaciones para la masificación de los sistemas de gestión energética en Industria colombiana”, Sci. tech, vol. 26, n.º 04, pp. 425–433, nov. 2021. https://doi.org/10.22517/23447214.24946

- arrow_upward [106] Red colombiana de conocimiento en eficiencia energetica - RECIEE, “Boletín RECIEE # 10”, 2017.

- arrow_upward [107] Departamento Nacional de Planeación - DNP, Enersinc, “Energy Demand Situation in Colombia”, 2017.

- arrow_upward [108] Unidad de Planeación Minero Energética UPME, Invierta y gane con energía: Guia práctica para la aplicación de los incentivos tributarios de la Ley 1715 de 2014, 2014. https://www1.upme.gov.co/Documents/Cartilla_IGE_Incentivos_Tributarios_Ley1715.pdf

- arrow_upward [109] Organización de Naciones Unidas - ONU, “United Nations Climate Change COP26, Together for our planet” 2021. https://www.un.org/en/climatechange/cop26

- arrow_upward [110 R. E. Jara, “Con compromisos distintos y sin una estrategia común: así llega Latinoamérica a la COP26”, 2021. https://www.emol.com/noticias/Internacional/2021/11/02/1037125/latinoamerica-estrategia-cop26.html. Published 2021

- arrow_upward [111] El Tiempo, “Los compromisos del Gobierno colombiano en la COP 26”, 2021. https://www.eltiempo.com/politica/gobierno/cop26-los-compromisos-del-gobierno-colombiano-629164

PDF

PDF