Effect of Baking Temperature on Carotenoids and Provitamin A in Bread made with Mandarin (Citrus reticulata) Epicarp Extract

Efecto de la temperatura de horneado en carotenoides y provitamina A en pan elaborado con extracto de epicarpio de mandarina (Citrus reticulata)

Received: June 13, 2023

Accepted: November 30, 2023

Available: December 29, 2023

L. E. Ordóñez-Santos, J. Esparza-Estrada, P. Vanegas-Mahecha, “Effect of Baking Temperature on Carotenoids and Provitamin A in Bread made with Mandarin (Citrus reticulata) Epicarp Extract,” TecnoLógicas, 26, nro. 58, e2755, 2023. https://doi.org/10.22430/22565337.2755

Highlights

Highlights

Abstract

Consumers are interested in products with functional properties that contribute to their well-being and health. An alternative source of functional ingredients would be the by-products of the citrus industry, which can be used as natural additives in baked products. Therefore, the objective of this study was to evaluate the effect of temperature on the concentration of carotenoids and provitamin A when baking bread in a temperature range of 160-200 ºC. We studied the thermal degradation kinetics and thermodynamic parameters of the carotenoids β-carotene, α-carotene, β-cryptoxanthin, lycopene, and provitamin A in bread dough samples made with mandarin epicarp lipid extract baked at three temperatures (160, 180, and 200 ºC). The results showed that carotenoid pigments and provitamin A are significatively reduced (p < 0.05) as baking time and temperature increase, and the degradation of bioactive compounds was set to a first-order kinetic R2 > 0.83. Thermic resistance values (z) and activation energy (Ea) during the baking process of bread showed that β-carotenes are an unstable thermal phytochemical, followed by provitamin A, α-carotenoid, lycopene, and β-cryptoxanthin. In this research, it can be concluded that the results would be important for the design and optimization of baked bread, as it will allow to maximize the levels of these micronutrients.

Keywords: Retinol equivalent activity, kinetic energy, β-carotene, entropy coding, half-life time

Resumen

Los consumidores están interesados en productos con propiedades funcionales que contribuyan a su bienestar y salud. Una fuente alternativa de ingredientes funcionales serían los subproductos de la industria de los cítricos, que pueden ser utilizados como aditivos naturales en productos horneados. Por lo tanto, el objetivo de este estudio fue evaluar el efecto de la temperatura sobre la concentración de carotenoides y provitamina A al hornear pan en un rango de temperatura de 160-200 ºC. Se estudió la cinética de degradación térmica y los parámetros termodinámicos de los carotenoides β-caroteno, α-caroteno, β-criptoxantina, licopeno y provitamina A en muestras de masa de pan elaboradas con extracto lipídico de epicarpio de mandarina horneadas a tres temperaturas (160, 180 y 200 ºC). Los resultados mostraron que los pigmentos carotenoides y la provitamina A se reducen significativamente (p < 0,05) a medida que aumenta el tiempo y la temperatura de horneado, y la degradación de los compuestos bioactivos se establece en una cinética de primer orden R2 > 0,83. Los valores de resistencia térmica (z) y energía de activación (Ea) durante el proceso de horneado del pan mostraron que los β-caroteno son un fitoquímico térmico inestable, seguidos por la provitamina A, α-caroteno, licopeno y β-criptoxantina. En esta investigación se puede concluir que los resultados serían importantes para el diseño y optimización de la cocción del pan, ya que permitirá maximizar los niveles de estos micronutrientes.

Palabras clave: Actividad equivalente de retinol, energía cinética, β-caroteno, condición de entropía, tiempo de vida media.

1. INTRODUCTION

It is expected that the year 2025 will see sales of 246.20 billion dollars in the global market for bakery products, and the bread market will have revenue equaling 460.40 million dollars [

Fruit by-products are a potential source for use in this industry because they are reservoirs of functional ingredients, such as fiber, minerals, and phytochemicals [

In addition, [

2. MATERIALS AND METHODS

2.1 Obtaining the lipid extract from mandarin epicarp

Once mandarin epicarp flour was obtained according to [

2.2 Bread with lipid extract from mandarin epicarp

The bread was obtained following the methodology of [

2.3 Determination of physicochemical parameters in bread

The moisture content and weight loss in the samples were determined according to [

2.4 Determination of kinetic and thermodynamic parameters

In accordance the studies by [

(1)

(1)

Where, C0 and Ct are the concentration of the molecules of interest at time 0 and t, k is the degradation rate constant (min-1) and t is the thermal processing time. (D, min), (t0.5, min), Q10, and (z, °C) are the decimal reduction time, half-life time, temperature coefficient and thermal resistance coefficient, respectively. The kinetic parameters were estimated using the Arrhenius equation according to [

2.5 Statistical analysis

Each of the experiments was carried out in triplicate and the results were expressed as mean values. One-way ANOVA (p < 0.05) was used to study the effect of temperature on the phytochemicals of interest, and the degradation of these molecules was modeled using analytical regression. The analyzes were carried out in SPSS for Windows v.25. and Excel software (version 10, Microsoft Corporation, Redmond, WA, USA). The correlation coefficient R2 was calculated to determine the goodness of fit.

3. RESULTS AND DISCUSSION

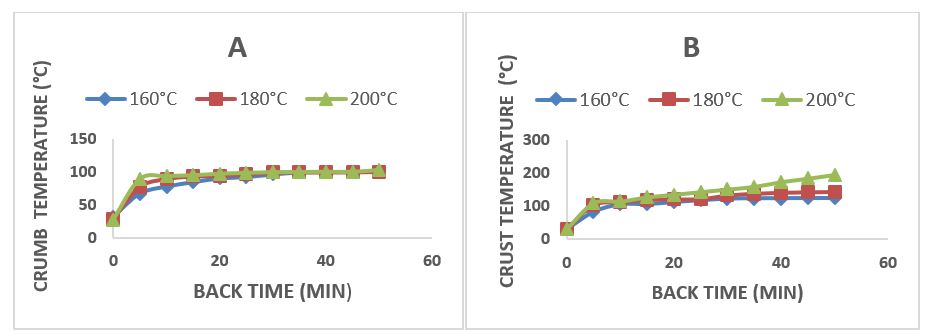

3.1 Bread temperature profile during baking

The temperature profiles of the crumb and crust when baking the bread at 160 °C, 180 °C and 200 °C are shown in Figure 1. The temperature increases in the bread crumb followed a sigmoidal pattern, increasing gradually until it became constant at 100 °C. These results agree with [

At the beginning, the temperature of the crust was less than 100 °C; at this point, no vaporization occurred through boiling. The production of water vapor in the pores through evaporation was negligible. The temperature increased from the flow of incoming heat in the second baking phase, when the temperature of the crust was higher than 100 °C. At this point, the boiling temperature was reached, and the matter entered the boiling regime. The liquid water turned into steam until exhausted [

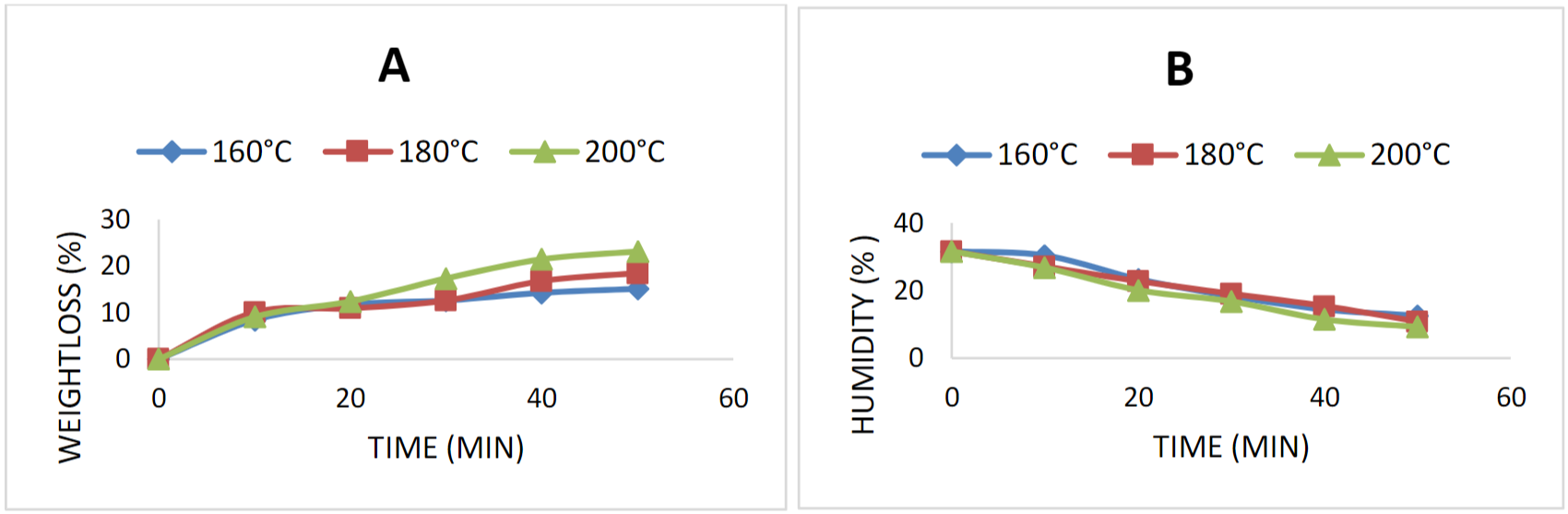

3.2 Loss of weight and moisture during bread baking

Figure 2 shows the loss of weight and moisture in the bread during the baking process. At the end of the process, the samples had a weight loss of 15.11 ± 1.55, 18.49 ± 0.16 and 23.14 ± 0.19 and a moisture loss of 12.60 ± 0.17, 10.87 ± 0.15 and 9.26 ± 0.06 % with baking temperatures of 160 °C, 180 °C, and 200 °C, respectively. These results agree with the studies by Lara et al. [

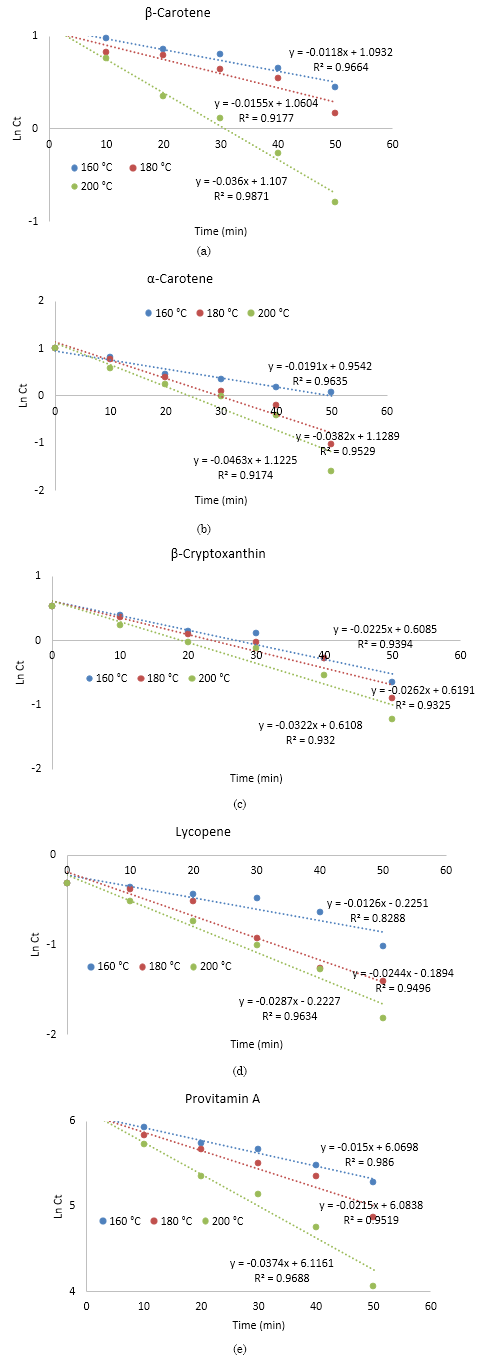

3.3 Thermal kinetics and thermodynamic analysis of carotenoids and provitamin A in bread

The initial concentration of carotenoids in the raw dough enriched with mandarin epicarp extract (20 g of extract/100 g of dough) included β-carotene (2.88 µg/g), α-carotene (2.74 µg/g), β-cryptoxanthin (1.70 µg/g), lycopene (0.73 µg/g), and provitamin A (425.24 µg RAE/g). The carotenoid pigments and provitamin A were significantly reduced (p < 0.05) as the bread baking time and temperature increased. These results are consistent with those recorded in other studies, with a degradation of carotenoids after baking processes [

Figure 3 and Table 1 show that, when increasing the intensity of the baking treatment, the constant degradation rate of carotenoids and provitamin A in bread increased, and the correlation coefficient for all kinetics was R2> 0.83. The first-order kinetics of degradation explained the changes in the concentration of carotenoid pigments and provitamin A in the bread after baking. The other kinetic parameters of bread during baking are listed in Table 1. The kinetic parameters D, t0.5, Q10 and z validate that carotenoids and provitamin A are thermolabile compounds during bread baking, presenting different levels of resistance between molecules. The thermal resistance value (z) reports that β-cryptoxanthin presented the highest resistance, followed by lycopene, α-carotene, provitamin A, and β-carotene in the temperature range 160-200ºC (Table 1).

Source: Created by the authors.

Source: Created by the authors.

| Compound | T (°C) | k (min-1) | R2 | D (min) | t½(min) | Q10 (160-00°C) |

z (°C) |

| β- Carotene | 160 | 0.0118 | 0.970 | 195.13 | 58.74 | 1.32 | 82.57 |

| 180 | 0.0155 | 0.920 | 148.55 | 44.72 | |||

| 200 | 0.0360 | 0.990 | 63.96 | 19.25 | |||

| α- Carotene | 160 | 0.0191 | 0.960 | 120.55 | 36.29 | 1.25 | 104.02 |

| 180 | 0.0382 | 0.950 | 60.28 | 18.15 | |||

| 200 | 0.0463 | 0.920 | 49.73 | 14.97 | |||

| β-Cryptoxanthin | 160 | 0.0225 | 0.940 | 102.34 | 30.81 | 1.09 | 256.95 |

| 180 | 0.0262 | 0.930 | 87.88 | 26.46 | |||

| 200 | 0.0322 | 0.932 | 71.51 | 21.53 | |||

| Lycopene | 160 | 0.0126 | 0.830 | 182.74 | 55.01 | 1.23 | 111.88 |

| 180 | 0.0244 | 0.950 | 94.37 | 28.41 | |||

| 200 | 0.0287 | 0.963 | 80.23 | 24.15 | |||

| Provitamin A | 160 | 0.0150 | 0.986 | 153.51 | 46.21 | 1.26 | 100.81 |

| 180 | 0.0215 | 0.952 | 107.10 | 32.24 | |||

| 200 | 0.0374 | 0.967 | 61.57 | 18.53 |

To date, research on the thermal degradation of carotenoids and provitamin A in bread during baking processes has not been reported in the scientific literature; however, other studies have applied the hot air dehydration method in different matrices: [

The thermal sensitivity of β-carotene in this study has also been reported by [

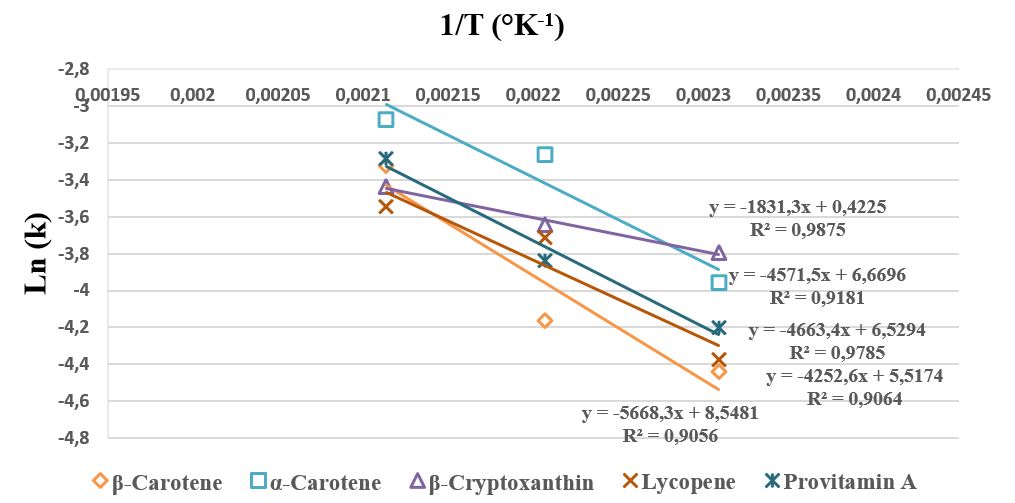

Figure 4 shows the effect of temperature on the constant degradation rate of the carotenoids and provitamin A during the bread baking process in the range of 160 to 200 ºC, which conformed to the Arrhenius model (R2 > 0.91). The activation energy (Ea) during the bread baking process presented the highest value in β-Carotene, followed by provitamin A, α-carotene, lycopene and β-cryptoxanthin (Table 2). Authors such as [

Source: Created by the authors.

| Compound | T (°C) | Ea (kJ mol-1) |

R2 | ΔH (kJ mol-1) |

ΔG (kJ mol-1) |

ΔS (kJ mol-1) |

| β- Carotene | 160 | 47.13 | 0.910 | 43.82 | 137.89 | -217.17 |

| 180 | 43.66 | 143.40 | -220.11 | |||

| 200 | 43.49 | 146.58 | -217.88 | |||

| α- Carotene | 160 | 38.01 | 0.920 | 34.71 | 136.16 | -234.21 |

| 180 | 34.54 | 140.00 | -232.73 | |||

| 200 | 34.37 | 145.59 | -235.06 | |||

| β-Cryptoxanthin | 160 | 15.23 | 0.990 | 11.92 | 135.57 | -285.45 |

| 180 | 11.76 | 141.42 | -286.14 | |||

| 200 | 11.59 | 147.02 | -286.23 | |||

| Lycopene | 160 | 35.36 | 0.910 | 32.05 | 137.65 | -243.79 |

| 180 | 31.89 | 141.69 | -242.31 | |||

| 200 | 31.72 | 147.47 | -244.64 | |||

| Provitamin A | 160 | 38.77 | 0.980 | 35.47 | 137.02 | -234.46 |

| 180 | 35.30 | 142.17 | -235.82 | |||

| 200 | 35.14 | 146.43 | -235.22 |

For provitamin A, [

The values of the activation enthalpy (ΔH), inactivation free energy (ΔG), and activation entropy (ΔS) in the degradation of the carotenoids and provitamin A during the baking process at each of the evaluated temperatures can be observed in (Table 2). The positive values of ΔH and ΔG and the negative results of ΔS during the bread baking showed that the degradation of the carotenoids and provitamin A was an endothermic reaction that was spontaneous in nature. The studies carried out by [

4. CONCLUSIONS

This study showed that the kinetic and thermodynamic model predicted changes in the carotenoids and provitamin A during the bread baking process (160 to 200 ºC). The thermal degradation kinetics followed a first-order reaction with a correlation coefficient of R2 > 0.83 in all bioactive compounds evaluated in the bread. The constant degradation rate of the carotenoids and provitamin A during the bread baking (160 to 200 ºC) was adjusted to the Arrhenius model (R2 > 0.91). The parameters ∆H, ∆G, and ∆S demonstrated that the carotenoid degradation relationship followed an endothermic, non-spontaneous reaction and had less structural freedom than the reactants. These results are important for the design and optimization of bread baking processes since they will maximize the levels of bioactive compounds in this food type.

5. ACKNOWLEDGMENTS AND FUNDING

This research was supported with resources by the Universidad Nacional de Colombia, sede Palmira, with the Hermes 42088 Project.

CONFLICTS OF INTEREST

The authors declare that they do not have any type of conflict of interest in the work reported in this document.

AUTHOR CONTRIBUTIONS

Luis Eduardo Ordoñez-Santos: Conceptualization, Methodology, Validation, Formal analysis, Writing - Original Draft, Project administration. Jessica Esparza-Estrada: Investigation, Validation Software, Formal analysis, Review, and editing. Pedro Vanegas-Mahecha: Methodology, Validation, Formal analysis.

7. REFERENCES

- arrow_upward [1] Grand View Research, “Bakery Products Market Size, Share & Trends Analysis Report By Distribution Channel (Specialty Stores, Convenience Stores), By Product (Cakes & Pastries, Breads & Rolls, Cookies, Tortillas, Pretzels), And Segment Forecasts, 2019 – 2025,” San Francisco, California, Rep. GVR-3-68038-229-7, 2017. Available: https://www.grandviewresearch.com/industry-analysis/bakery-products-market/

- arrow_upward [2] M. Alda, “Bread – Worldwide,” Statista.com. Accessed: Apr. 16, 2023. Available: https://www.statista.com/outlook/40050100/100/bread/worldwide/

- arrow_upward [3] B. Sayed-Ahmad et al., “Effect of addition of fennel (Foeniculum vulgare L.) on the quality of protein bread,” Proc. Latv. Acad. Sci. Sect. B Nat. Exact Appl. Sci., vol. 71, no. 6, pp. 509–514, Jan. 2017. https://doi.org/10.1515/prolas-2017-0088

- arrow_upward [4] R. Tolve et al., “Wheat bread fortification by grape pomace powder: Nutritional, technological, antioxidant, and sensory properties,” Foods, vol. 10, no. 1, p. 75, Jan. 2017. https://doi.org/10.3390/foods10010075

- arrow_upward [5] Z. E. Martins, O. Pinho, and I. M. P. L. V. O. Ferreira, “Food industry by-products used as functional ingredients of bakery products,” Trends Food Sci. Technol., vol. 67, pp. 106–128, Sep. 2017. https://doi.org/10.1016/j.tifs.2017.07.003

- arrow_upward [6] D. Santos, J. A. Lopes da Silva, and M. Pintado, “Fruit and vegetable by-products’ flours as ingredients: A review on production process, health benefits and technological functionalities,” LWT, vol. 154, p. 112707, Jan. 2022. https://doi.org/10.1016/j.lwt.2021.112707

- arrow_upward [7] J. Tian et al., “Domestic cooking methods affect the phytochemical composition and antioxidant activity of purple-fleshed potatoes,” Food Chem., vol. 197, pp. 1264–1270, Apr. 2016. https://doi.org/10.1016/j.foodchem.2015.11.049

- arrow_upward [8] C. M. Ajila, K. Leelavathi, and U. J. S. Prasada Rao, “Improvement of dietary fiber content and antioxidant properties in soft dough biscuits with the incorporation of mango peel powder,” J. Cereal Sci., vol. 48, no. 2, pp. 319–326, Sep. 2008. https://doi.org/10.1016/j.jcs.2007.10.001

- arrow_upward [9] V. Nour, M. E. Ionica, and I. Trandafir, “Bread enriched in lycopene and other bioactive compounds by addition of dry tomato waste,” J. Food Sci. Technol., vol. 52, no. 12, pp. 8260–8267, Jul. 2015. https://doi.org/10.1007/s13197-015-1934-9

- arrow_upward [10] L. C. R. dos Reis, E. M. P. Facco, M. Salvador, S. H. Flôres, and A. de O. Rios, “Characterization of orange passion fruit peel flour and its use as an ingredient in bakery products,” J. Culin. Sci. Technol., vol. 18, no. 3, pp. 214–230, Dec. 2018. https://doi.org/10.1080/15428052.2018.1564103

- arrow_upward [11] L. E. Ordoñez-Santos, J. Esparza-Estrada, and P. Vanegas-Mahecha, “Potencial agroindustrial del epicarpio de mandarina como alternativa de colorante natural en pan,” TecnoLógicas, vol. 23, no. 48, pp. 17–29, 2020.

- arrow_upward [12] L. E. Ordóñez-Santos, J. Esparza-Estrada, and P. Vanegas-Mahecha, “Ultrasound-assisted extraction of total carotenoids from mandarin epicarp and application as natural colorant in bakery products,” Lebenson. Wiss. Technol., vol. 139, p. 110598, Mar. 2021. https://doi.org/10.1016/j.lwt.2020.110598

- arrow_upward [13] A. Putranto, X. D. Chen, and W. Zhou, “Bread baking and its color kinetics modeled by the spatial reaction engineering approach (S-REA),” Food Res. Int., vol. 71, pp. 58–67, May. 2015. https://doi.org/10.1016/j.foodres.2015.01.029

- arrow_upward [14] S. Onacik-Gür, A. Szafrańska, M. Roszko, and S. Stępniewska, “Interaction of dough preparation method, green tea extract and baking temperature on the quality of rye bread and acrylamide content,” LWT, vol. 154, p. 112759, Jan. 2022. https://doi.org/10.1016/j.lwt.2021.112759

- arrow_upward [15] P. N. Panirani, H. Darvishi, A. Hosainpour, and N. Behroozi-Khazaei, “Comparative study of different bread baking methods: Combined ohmic – infrared, ohmic – conventional, infrared – conventional, infrared, and conventional heating,” Innov. Food Sci. Emerg. Technol., vol. 86, p. 103349, Jun. 2023. https://doi.org/10.1016/j.ifset.2023.103349

- arrow_upward [16] A. Fratianni et. al., “Kinetics of carotenoids degradation and furosine formation in dried apricots (Prunus armeniaca L.),” Food Res. Int., vol. 99, pp. 862–867, Sep. 2017. https://doi.org/10.1016/j.foodres.2016.12.009

- arrow_upward [17] I. Gheonea (Dima) et. al., “Investigations on thermostability of carotenoids from tomato peels in oils using a kinetic approach,” J. Food Process. Preserv., vol. 44, no. 1, p. e14303 Jan. 2020. https://doi.org/10.1111/jfpp.14303

- arrow_upward [18] L. E. Ordóñez-Santos and J. Martínez-Girón, “Thermal degradation kinetics of carotenoids, vitamin C and provitamin A in tree tomato juice,” Int. J. Food Sci. Technol., vol. 55, no. 1, pp. 201–210, Jun. 2020. https://doi.org/10.1111/ijfs.14263

- arrow_upward [19] AOAC, “Official Methods of Analysis of Aoac International, Agricultural Chemicals, Contaminants, Drugs,” W. Horwitz, Eds, 17th Edn, Maryland, EE.UU, 2000. https://books.google.com.co/books/about/Official_Methods_of_Analysis_of_AOAC_Int.html?id=Bbn0oAEACAAJ&redir_esc=y

- arrow_upward [20] E. Lara, P. Cortés, V. Briones, and M. Perez, “Structural and physical modifications of corn biscuits during baking process,” LWT - Food Sci Techno., vol.44, no. 3, pp. 622–630, Apr. 2011. https://doi.org/10.1016/j.lwt.2010.10.007

- arrow_upward [21] L. E. Ordóñez-Santos, J. Martínez-Girón, and M. E. Arias-Jaramillo, “Effect of ultrasound treatment on visual color, vitamin C, total phenols, and carotenoids content in Cape gooseberry juice,” Food Chem., vol. 233, pp. 96–100, Oct. 2017. https://doi.org/10.1016/j.foodchem.2017.04.114

- arrow_upward [22] C. Dhuique-Mayer, M. Tbatou, M. Carail, C. Caris-Veyrat, M. Dornier, and M. J. Amiot, “Thermal degradation of antioxidant micronutrients in citrus juice: Kinetics and newly formed compounds,” J. Agric. Food Chem., vol. 55, no. 10, pp. 4209–4216, Apr. 2007. https://doi.org/10.1021/jf0700529

- arrow_upward [23] X. Sui, P. Y. Yap, and W. Zhou, “Anthocyanins during baking: Their degradation kinetics and impacts on color and antioxidant capacity of bread,” Food Bioproc. Tech., vol. 8, pp. 983–994, Jan. 2015. https://doi.org/10.1007/s11947-014-1464-x

- arrow_upward [24] A. Hidalgo, A. Brandolini, and C. Pompei, “Carotenoids evolution during pasta, bread and water biscuit preparation from wheat flours,” Food Chem., vol. 121, no. 3, pp. 746-751, Aug. 2010. https://doi.org/10.1016/j.foodchem.2010.01.034

- arrow_upward [25] E.-S. M. Abdel-Aal, L. Mats, and I. Rabalski, “Identification of carotenoids in hairless canary seed and the effect of baking on their composition in bread and muffin products,” Molecules, vol. 27, no. 4, p. 1307, Feb. 2022. https://doi.org/10.3390/molecules27041307

- arrow_upward [26] J. Liu, A. Zamora, M. Castillo, and J. Saldo, “Using front-face fluorescence spectroscopy for prediction of retinol loss in milk during thermal processing,” LWT, vol. 87, pp. 151–157, Jan. 2018. https://doi.org/10.1016/j.lwt.2017.08.073

- arrow_upward [27] C. Dincer, M. Karaoglan, F. Erden, N. Tetik, A. Topuz, and F. Ozdemir, “Effects of baking and boiling on the nutritional and antioxidant properties of sweet potato [Ipomoea batatas (L.) lam.] cultivars,” Plant Foods Hum. Nutr., vol. 66, pp. 341–347, Nov. 2011. https://doi.org/10.1007/s11130-011-0262-0

- arrow_upward [28] E. Muntean, “Effect of Thermal Processing on Carotenoids in Fortified Bread,” Engineering Proceedings, vol. 37, no. 1, p. 70, May. 2023. https://doi.org/10.3390/ECP2023-14694

- arrow_upward [29] A. Saxena, T. Maity, P. S. Raju, and A. S. Bawa, “Degradation kinetics of colour and total carotenoids in jackfruit (Artocarpus heterophyllus) bulb slices during hot air drying,” Food Bioproc. Tech., vol. 5, pp. 672–679, Jul. 2010. https://doi.org/10.1007/s11947-010-0409-2

- arrow_upward [30] A. Fratianni et al., “Kinetics of carotenoids degradation and furosine formation in dried apricots (Prunus armeniaca L.),” Food Res. Int., vol. 99, pp. 862–867, Sep. 2017. https://doi.org/10.1016/j.foodres.2016.12.009

- arrow_upward [31] Z. Kotíková, M. Šulc, J. Lachman, V. Pivec, M. Orsák, and K. Hamouz, “Carotenoid profile and retention in yellow-, purple- and red-fleshed potatoes after thermal processing,” Food Chem., vol. 197, pp. 992–1001, Apr. 2016. https://doi.org/10.1016/j.foodchem.2015.11.072

- arrow_upward [32] Q. Lu, Y. Peng, C. Zhu, and S. Pan, “Effect of thermal treatment on carotenoids, flavonoids and ascorbic acid in juice of orange cv. Cara Cara,” Food Chem., vol. 265, pp. 39–48, Nov. 2018.https://doi.org/10.1016/j.foodchem.2018.05.072

- arrow_upward [33] X. Ya-dong et al. “Thermal degradation kinetics of all-trans and cis-carotenoids in a light-induced model system,” Food Chem., vol. 239, pp. 360–68, Jan. 2018. https://doi.org/10.1016/j.foodchem.2017.06.107

- arrow_upward [34] I. Gheonea (Dima) et al., “Investigations on thermostability of carotenoids from tomato peels in oils using a kinetic approach,” J. Food Process. Preserv., vol. 44, no. 1, Jan. 2020. https://doi.org/10.1111/jfpp.14303

- arrow_upward [35] D. C. Murador, D. T. da Cunha, and V. Vera de Rosso, “Effects of cooking techniques on vegetable pigments: A meta-analytic approach to carotenoid and anthocyanin levels,” Food Res. Int., vol. 65, pp. 177–183, Nov. 2014. https://doi.org/10.1016/j.foodres.2014.06.015

- arrow_upward [36] M. I. Minguez-Mosquera and M. Jaren-Galan, “Kinetics of the decolouring of carotenoid pigments,” J. Sci. Food Agric., vol. 67, no. 2, pp. 153–161, Feb. 1995. https://doi.org/10.1002/jsfa.2740670203

- arrow_upward [37] L. K. Henry, G. L. Catignani, and S. J. Schwartz, “Oxidative degradation kinetics of lycopene, lutein, and 9‐cis and all‐trans β‐carotene,” J. Am. Oil Chem. Soc., vol. 75, no. 7, pp. 823–829, Jul. 1998. https://doi.org/10.1007/s11746-998-0232-3

- arrow_upward [38] C. S. Boon, D. J. McClements, J. Weiss, and E. A. Decker, “Factors influencing the chemical stability of carotenoids in foods,” Crit. Rev. Food Sci. Nutr., vol. 50, no. 6, pp. 515–532, Jun. 2010. https://doi.org/10.1080/10408390802565889

- arrow_upward [39] D.B. Rodriguez-Amaya, “Natural food pigments and colorants,” Curr. Opin. Food Sci., vol. 7, pp. 20–26, Feb. 2016. https://doi.org/10.1016/j.cofs.2015.08.004

PDF

PDF